VARIABLE POWER Advanced MPPT algorithms for PV modules

Related Vendors

We all know that variable power sources like photovoltaic modules cannot be used for long periods due to their uncontrollably fluctuating functionality in unfavorable weather conditions. In such cases, an advanced set of techniques known as “Maximum Power Point Tracking” allows you to draw the required energy out of the system. This article explains advanced MPPT algorithms for PV modules.

Variable power sources generate electric power for a short period. Such intermittent power-generating systems depend heavily on a set of external conditions. VRE (Variable Renewable Energy) sources including solar panels, wind turbines, hydroelectricity plants, optical power devices, and biomass-based systems cannot be dispatched for a long time due to their inability to meet a certain set of conditions for a specific time frame. For example, sunlight is not available 24 hours for solar technology to function, low-speed winds halt electricity generation, etc.

What is MPPT and why should we use it?

It must be noted that a photovoltaic module is a system where solar energy is converted into DC electricity using interconnected solar cells (or photovoltaic cells). MPPT is the abbreviation for “Maximum Power Point Tracking”. It is an algorithm that maximizes energy extraction as conditions vary during the operation of variable energy sources.

:quality(80)/p7i.vogel.de/wcms/ed/d8/edd83d7b6f7038c7c15a46fdf2bc6fb7/96879394.jpeg)

BASIC KNOWLEDGE - RENEWABLE ENERGY SOURCES

What is renewable energy? Definition, types, and challenges

MPPT performs the “smartest” operation to avoid power wastage. MPPT calculates PV module power delivery and compares it to the actual power requirement needed to be delivered to the load. It automatically converts and delivers the required power to drive the load. It is important to note that MPPT does not deliver excess power that would result in heat loss. Only “required” power is delivered to the load.

The efficiency of a PV module is dependent upon the amount of available:

- Irradiation (Sunlight)

- Shading

- Angle and orientation

- Temperature

- Load’s electrical characteristic- mainly impedance

- Design considerations

Theory behind MPPT

As mentioned above, solar technologies have varying relationships to the load. Change in ongoing power delivery is required to enable the highest power transfer. When power is transferred from the PV module to the load during varying conditions, load impedance provides maximum change in power transfer compared to other above-listed factors.

Noting this fact, the PV module is optimized to produce a change in impedance, which enables the highest power transfer. This optimal load characteristic is called “Maximum Power Point” or MPP. The MPPT algorithm adjusts load characteristics during variable conditions to provide maximum required power efficiency.

We use the word “tracking” because MPPT adjusts or optimizes the power delivery. The power transfer efficiency of a PV module depends on its ability to operate at the MPP, at which the device can generate the maximum required amount of power during varying external conditions.

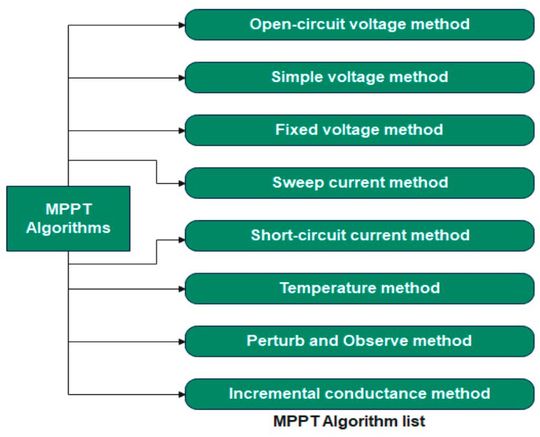

Advanced MPPT algorithms

The maximum power produced during variable conditions with the help of MPPT algorithms is called “Maximum Peak Power” or “Peak Power”. To extract maximum power, MPPT algorithms are embedded in “charge” microcontrollers of PV modules.

The voltage at which maximum power is transferred is called “Maximum Power Point Voltage” (MPP voltage) and the current is called “Maximum Power Point Current” (MPP current). MPP power is calculated using values of MPP voltage and current.

MPP Power = MPP Voltage x MPP current

1. Voltage Methods

Open-voltage method

The device is abruptly turned off to temporarily halt power delivery to the load. The voltage present when no current flows through the circuit is known as open-circuit voltage. The microcontroller resumes operation to adjust the output voltage to a value that is about 0.76 of open-circuit voltage. Setting such a value regulates the output voltage. This value stands close to MPP and is selected through data modeling and approximation.

Single voltage method

The single-voltage method programs the microcontroller with a resistor and a thermistor. This method sets a pre-defined voltage value to approximate the voltage at which the PV module will produce its maximum power output. In short, it determines the MPP voltage.

Fixed voltage method

When MPP tracking fails, a fixed output voltage method is implemented. The output voltage is kept constant under all sets of operational conditions. However, this method is less frequently used compared to other voltage methods.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/65/cb/65cb9c3a03849/webinar-efficient-electrolysis-through-comprehensive-power-conversion-solutions-coverbild.jpeg)

GREEN HYDROGEN

Efficient Electrolysis through Comprehensive Power Conversion Solutions

2. Current methods

Sweep current method

The first method is to use a sweep waveform to calculate the I-V relationship of the PV module and update it regularly. The MPP current can be calculated using the transfer characteristics.

Short-circuit method

Another current-based method, the short circuit current method, uses a short-load pulse to drive the short-circuit condition. The short-circuit current is measured in such a condition. The MPP current is set at 0.9 times the short circuit current value. It is important to note that short-circuit current value increases with an increase in temperature.

3. Temperature method

As mentioned above, several factors influence the efficiency of power delivery to the load in a PV module. This method considers temperature but ignores the effects of other factors such as irradiance, shading, design considerations, and load characteristics.

The temperature method calculates the value of MPP voltage using the temperature voltage equation. It must be noted that MPP shifts to low voltages and different current values at higher temperatures. However, the efficiency of PV modules decreases at high temperatures.

4. Perturb and Observe

The P&O method is frequently used due to ease of implementation, simplicity, and accuracy. Depending upon the increment or decrement of output power, changes in voltage or current are made to calculate MPP. Simply put, the microcontroller slightly changes either voltage or current to observe the change in output power for finding out MPP.

The adjustments made to voltage or current are called step size. If power increases, adjustments are made in the same direction until the power stops increasing further. If the power decreases, the adjustments are made in the opposite direction. A large step size results in output power fluctuation, and a small step size results in a slow response.

The PV curve rises below MPP and falls above that point. As a result, this method is also called the hill climbing method. Implementing a predictive and adaptive hill climbing strategy is critical to achieving accuracy. However, this method is dependent hugely on irradiance. Low sunlight can result in output power oscillation.

5. Incremental conductance

The incremental conductance method is more effective than the P&O method but requires complex computation. Small incremental changes are made to the PV module voltage to observe changes in current values. Just as the word “incremental conductance” suggests, this method compares values of instantaneous conductance with incremental conductance to obtain MPP.

In simple words, this method finds the MPP by adjusting the voltage of the PV module. The microcontroller alters the duty cycle to change the PV module voltage. Then, the microcontroller samples incremental changes in current and voltage to predict the effect of the PV voltage change. When the PV voltage no longer changes, an MPP point is found.

MPPT as a device

The device in which the MPPT algorithm is embedded is called an MPPT solar charge controller. Technically, MPPT algorithms adjust load impedance to produce maximum peak power output.

The MPPT solar charge controller delivers maximum power from the PV module to the load. Simply put, an MPPT solar charge controller is a DC-DC converter. MPPT solar charge controller takes DC input from a PV module and converts it to high-frequency AC. Then, it converts AC to DC for delivery to the load.

MPPT compares the output voltage of the PV module to the load. It determines the amount of power that can fully drive the load. In short, the MPPT solar charge controller eliminates power wastage and enables the customer to pay for the amount of required power in all cases. MPPT solar charge controllers are most suitable for cold weather to provide the best results. Most MPPT devices are integrated into converters that are connected to the power grid, batteries, and motors.

Market value

Solar charge controller is presently a billion-dollar market that is expected to hit USD3.4 billion in 2031. There are other solar charge controllers available in the market like two-stage control and PWM-based solar charge controllers. However, MPPT solar charge controllers hold the maximum market share and have the highest growth potential compared to both technologies.

How does MPPT avoid power wastage?

The load (often battery) requires more than its rated voltage to fully charge. However, the PV module with the MPPT algorithm is capable of providing a much larger power, which may be lost as heat. MPPT extracts only the required power (less than it is capable of producing) and provides the best voltage to charge the battery. As a result, there is no waste of power and money.

References

(ID:50071568)

:quality(80)/p7i.vogel.de/wcms/ab/34/ab3461e7aabc1beab6f2598d09f1d9b4/0128949857v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/92/cd9200bfe196631a5fd7b5b85e25a5a6/0128944352v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/44/4d/444dda9649b5619c79d019c7dc1efcfc/0128974547v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/fd/a4fd7f7a395d6ecb4e79cfc558895b09/0129082772v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/0a/b10a283cdf3e5f156781a7273c71a7e0/0129107484v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:fill(fff,0)/p7i.vogel.de/companies/68/2c/682c3e2e9a195/logotype-rvb.jpeg)

:quality(80)/p7i.vogel.de/wcms/6d/1a/6d1adcfae7cfacf493a47c6ac3d33120/0124338052v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/91/a9/91a96266933db5bca40352e42f9fba96/0124626305v2.jpeg)