BASIC KNOWLEDGE Peltier effect: Fundamentals and applications

Related Vendors

This article describes the Peltier effect, how it is generated and how it can be used. The aim is for the reader to understand the thermoelectric phenomenon behind the heating of one surface and the cooling of another and the applications that have been developed taking advantage of these features. Without considering poor sealing aspects that reduce efficiency or attempting to have low thermal conductivity materials, this knowledge is intended for advanced and energy-saving applications where heating and cooling are present in a single system.

The importance of the Peltier effect lies in its quiet, compact, and maintenance-free solid-state device, which, through the application of electricity, enables both heating and cooling, offering advantages such as precise temperature control, the absence of harmful refrigerants, and reliable operation in harsh environments.

Specialized applications where Peltier devices are appropriate include cooling sensitive electronic devices, operating in zero gravity or vacuum, and achieving localized cooling. Despite being less efficient than traditional cooling, they have the benefit of not having moving parts or chemical refrigerants.

Many different industries use the Peltier effect for heating and cooling, including automotive, electronics, medical, telecommunications, and various industrial processes such as chip processing and energy applications.

Aiming to achieve precise temperature control for components and devices in a variety of applications, these modules are suitable for cooling medical equipment and sensitive sensors, as well as regulating temperatures in luxury car cup holders and personal refrigerators.

Next, we'll take a detailed look at how the Peltier effect is generated and present specific use cases in various fields where its benefits can be observed.

Conceptual explanations

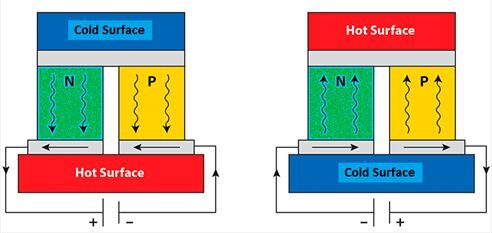

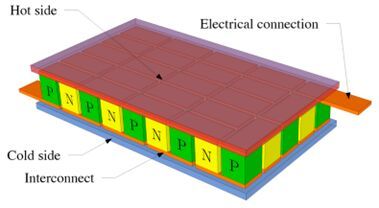

The Peltier effect is generated at the junction of p-type and n-type semiconductor materials, arranged in a circuit, when an electric current passes through it, causing heat to be absorbed or released at that junction, depending on the direction of the current.

Because electrons require different amounts of energy to move between different materials, this absorption or release of heat occurs, causing a corresponding temperature change to balance the energy difference.

The cooling effect occurs when electrons absorb energy from the junction between materials, moving from a lower energy state to a higher energy state. Conversely, the heating effect is generated when electrons release energy in the form of heat at the junction, moving from a higher energy state to a lower energy state.

Using the equation Q̇=πI, we can calculate the amount of heat generated or absorbed by the thermoelectric junction in a thermoelectric cooling (TEC) device. π is the Peltier coefficient, whose value depends on the direction of heat flow between the junctions, the junction temperature, and the material pair used.

One application where the Peltier system excels is in automotive air conditioning systems, while it is not recommended in thermoelectric generators (TEGs) due to fluctuations in current flow. In order to produce a heating or cooling load, an external electrical power input with reversible polarity is required in Peltier systems

Medical devices applications

To ensure accurate test results and the safe storage of medications and vaccines, TECs are responsible for maintaining stable temperatures in devices.

In high-sensitivity imaging systems, TECs regulate the temperature of critical components, preventing overheating and reducing noise in MRI and CT scanners. Image clarity and device lifespan are significantly improved by constant temperature control, positively impacting diagnostic accuracy and patient outcomes.

In laboratory devices such as polymerase chain reaction (PCR) machines, TECs control the rapid heating and cooling cycles that allow DNA sequences to be accurately amplified. This can be seen as a fundamental contribution to diagnostic testing and research, as the constant temperature changes provided by a TEC reduce cycle times and improve the accuracy of DNA replication.

In laser devices widely used in dermatology and ophthalmology, TECs ensure safe operation by preventing excessive heating of the laser emitters. This results in more reliable and effective treatments, thanks to the TEC modules' ability to maintain a stable laser temperature.

In portable refrigerators and storage units for blood, vaccines, and sensitive medications, we can find TEC modules as a key component. Aiming to preserve efficacy and safety, these devices maintain optimal temperatures during transport or in clinical settings. By eliminating the need for refrigerants, medical storage solutions are energy-efficient and environmentally friendly.

:quality(80)/p7i.vogel.de/wcms/9a/af/9aafa5ad3d3d900a6e22adf6d06a9bf5/0126877798v2.jpeg)

OPTIMIZATION TECHNIQUES

Heat management methods in power modules

Considerations to keep in mind

Heat transfer is reduced by the creation of air gaps when the module's contact surfaces are not flat or when the thermal paste or double-sided adhesive tape is used inappropriately, which is detrimental to the system's efficiency.

Proper operation of a TEC is hampered by the presence of undersized heat sinks or poor airflow, which limits its ability to dissipate heat from its hot side, leading to a drop in performance.

Designers propose addressing these problems through innovations in thermoelectric materials and integrated device design. The hot side of the device should have robust heat sinks and fans that efficiently dissipate heat.

To improve contact and heat transfer, thin, even layers of thermal paste should be placed between the Peltier element and the heat sinks, rather than thick layers of tape.

For more precise operation of the Peltier device, it is preferable to power it with a constant current source rather than a constant voltage source.

A solid understanding of how the Peltier effect is generated, combined with a mastery of key concepts such as semiconductor materials and temperature control, ensure successful thermoelectric cooling. Starting with a detailed analysis of the heat transfer phenomenon, this article addresses its benefits and applications in real-world use cases.

The purpose of this study is not to forward a Peltier module project on real equipment, as additional aspects affecting heat transfer, such as long-term reliability under high heat flux and semiconductor materials, are not taken into account. However, they serve as a starting point for temperature control procedures on many devices applications.

(ID:50589612)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/b9/62b980cddf5d6/ceramtec.png)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:quality(80)/p7i.vogel.de/wcms/9a/af/9aafa5ad3d3d900a6e22adf6d06a9bf5/0126877798v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/93/8d935dcd0623d224abf032aa1d73a5e2/0128635105v2.jpeg)