MODULATION TECHNIQUES Introduction to pulse width modulation (PWM) and its significance in power electronics

Related Vendors

Have you ever wondered what those regularly moving square pulses on that big machine in electronic laboratories mean? Those square pulses seen on an oscilloscope are a modulation technique called “Pulse Width Modulation”. The article discusses PWM in detail.

1. Pulse Width Modulation

To understand pulse width modulation, let us understand what modulation and pulse modulation is.

What is modulation?

Modulation is a technique that encodes the information signal on a carrier signal. The information signal contains all the important data and is also called the modulating signal. The primary function of the carrier signal is just to “carry” the information signal. A modulator varies the properties of the carrier signal and fits the information signal for transmission over the communication channel. At the receiving end, the demodulator recovers the original information signal from the carrier signal.

What is pulse modulation?

Pulse width modulation is an analog pulse modulation technique. In the pulse modulation technique, pulses in a train of pulses act as the carrier signal. Any one property of pulses including amplitude, width, or position is varied while others are kept constant to fit in the information signal. In accordance, there are three main types of analog pulse modulation techniques: Pulse Amplitude Modulation (PAM), Pulse Width Modulation (PWM), and Pulse Position Modulation (PPM). The remaining portion of the section discusses PWM in detail.

What is PWM (Pulse Width Modulation)?

PWM (Pulse Width Modulation) is a pulse modulation technique in which the width of the pulse is varied proportionally with the amplitude of the modulating signal. The data is encoded in the variation of the width of the pulses for transmission. The width of the pulse is varied but the amplitude and frequency of the same pulse remain constant throughout the operation. In simple words, PWM is a technique for modulating the width of pulses in a train of pulses to transmit information or control the power delivered to a load. By looking at the PWM waveform, you can simply call PWM a square wave of different widths.

PWM generation

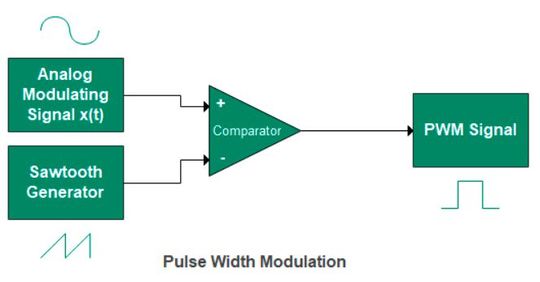

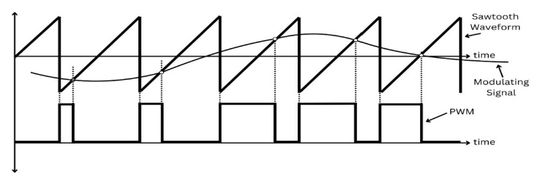

In a PWM generation system, there are three main components: The comparator, modulating signal, and sawtooth wave generating circuit. The time-varying modulating signal, represented by m(t) is an analog signal. In simple words, the modulating signal is the original information signal that contains data to be encoded and transmitted over the communication channel.

A sawtooth generator generates a non-sinusoidal signal. Simply put, a sawtooth wave generator produces the carrier signal signal. The carrier sawtooth signal is a sampling signal, also called a ramp signal. The modulating signal is fed to the non-inverting terminal of the comparator. The ramp sawtooth signal is fed to the inverting terminal of the comparator.

A comparator is a digital circuit that produces a digital output from one or more analog inputs. The comparator compares signals with a reference level. The output of a comparator is high when the amplitude of the modulating signal is higher than the ramp signal.

Similarly, the output of the comparator is low when the amplitude of the modulating signal is lower than the ramp signal. As a result, the comparator generates continuous streams of PWM digital signals at the output.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

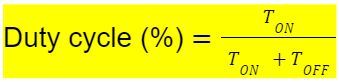

PWM duty cycle

In electronics, the duty cycle is the percentage of time for which a device remains on or high (1) in an interval. When a device stays on for a longer period in an interval, it corresponds to high power and efficiency. Similarly, low-duty cycles mean low power and efficiency.

As mentioned above, the data encoded is the width of the pulses. The width of pulses represents the on-time or high (1). In PWM, the duty cycle also represents efficiency and performance. PWM duty cycle represents square waves. The PWM duty cycle is the percentage of the ratio of on-time and total time of an interval. The total time is the addition of on-time and off-time.

PWM types

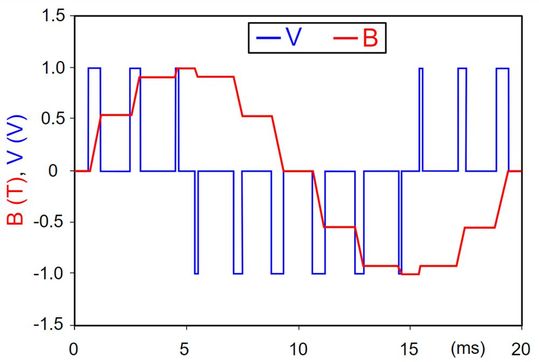

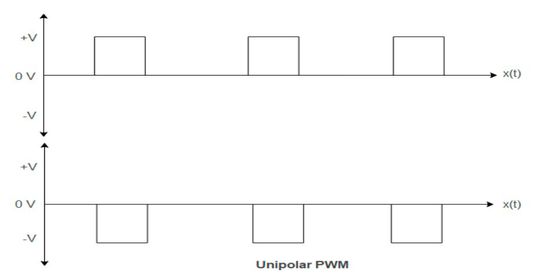

Unipolar PWM

A unipolar PWM is a type of PWM signal that swings between 0 Volts to a high voltage level or supply voltage. This type of signal can persist in the positive or negative portion of the waveform. Unipolar PWM is easier to implement and applications are relatively simple.

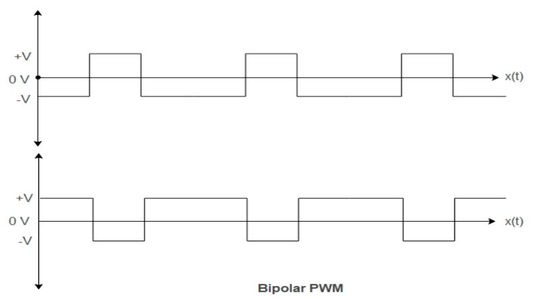

Bipolar PWM

A bipolar PWM is a type of PWM signal that swings between two voltage levels. This type of signal remains between the positive or negative portion of the waveform. Bipolar PWM is found in complex applications like bi-directional motor control, drivers, and many more.

:quality(80)/p7i.vogel.de/wcms/ed/d8/edd83d7b6f7038c7c15a46fdf2bc6fb7/96879394.jpeg)

BASIC KNOWLEDGE - RENEWABLE ENERGY SOURCES

What is renewable energy? Definition, types, and challenges

2. Applications of PWM in power electronics

Telecommunications

All these pulse modulation techniques are a part of digital communication technology. PWM is used in telecommunications to deliver information to the receiver. Using a monostable multivibrator, such as IC 555 (not an ideal choice) in a PWM circuit can also generate PPM (Pulse Position Modulation) signals.

Quick testing

In power electronics projects, PWM signal generation is fast and easier. Many microcontrollers, for example, Arduino, come with simple instructions to generate PWM signals. With connected circuitry, devices like CRO (Cathode Ray Oscilloscope) can be quickly set up to generate PWM outputs.

Dimming LEDs

As PWM is a stream of pulses of varying width, it can be used as an LED indicator that turns on and off repeatedly. LED indicators use PWM to go from light to dark gradually. Apple has been known to utilize PWM technology for LED blinking.

Audio amplification

PWM is used in power class D amplifiers to deliver high power to the loudspeaker in audio applications. Power class D amplifiers use PWM to support amplification and drive the output to offer high efficiency low power dissipation, and distortion in the output audio signal.

Drive Technology

PWM is implemented in servomechanisms for precise control of motor speeds and torques. The use of PWM enables controlling the speed of the motor by varying the supply voltage. This can be done by altering the duty cycle of the associated PWM signal.

:quality(80)/p7i.vogel.de/wcms/f9/29/f92903189bb36304a6bbc7ca5ba8e3fc/0117522391.jpeg)

POWER ELECTRONICS

Inverter vs converter: What's the difference?

Power Supply

SMPS (Switch Mode Power Supplies) and inverters use PWM to improve efficiency and optimize power transfer. In voltage regulation, PWM constantly helps to maintain the same voltage level through duty cycle adjustment. Moreover, PWM is used frequently with semiconductor switches to turn on and off any device rapidly.

Renewable Energies

PWM is used in the designing of microinverters used in wind energy projects to maximize DC power utilization. PWM, along with MOSFET switches, is used to connect and disconnect the solar panel from the battery. Other uses of PWM in renewables include battery charging.

3. Technical Challenges and Solutions

Electromagnetic Interference (EMI)

EMI through PWM is an unwanted phenomenon that leads to improper functioning of an electronic device. The optimal solution to deal with PWM EMI is the effective design of the detection and protection circuits. Using limiter circuits like clippers and low-pass filters can easily eliminate EMI problems.

Heat Generation

A significant amount of heat is generated in PWM technology due to associated circuitry like power semiconductor switches and amplifiers. Effective thermal management and implementation of cooling mechanisms are the key to eliminating heat-related issues.

:quality(80)/p7i.vogel.de/wcms/73/0f/730f6acafa3daf8ca82d985bf55673ec/0113679029.jpeg)

WAVEFORM SHAPING

Applications of Diodes: Clipper and Clamper Circuits

4. Future Prospects of PWM in Power Electronics

Advances in Semiconductor Technology

As mentioned above, PWM technology is compatible with various silicon-based semiconductor switches: MOSFETs and IGBTs. Innovations in WBG semiconductors can enhance the efficiency of PWM systems due to effective thermal management. SiC and GaN switches may promote high-frequency operation of PWM in various control applications.

Intelligent Control Systems

PWM duty cycle adjustment has already been used in control systems for a long time. Intelligent control systems implement PWM for controlling the speed of robots in robotics applications. Moreover, the latest machine learning and AI applications use PWM for neural and adaptive networks.

References

John G. Proakis and Masoud Salehi. (2013). Digital Communications. McGraw Hill International Edition

Experience power electronics for E-Mobility & Energy Storage

Would you like to experience the trends in power electronics for E-Mobility and Energy Storage at first hand? Become part of the PCIM Europe exhibition from 11 – 13 June 2024 in Nuremberg, Germany. There, you can experience a stage with top-class presentations as well as Live Product Demos at the stand of specialized exhibitors.

Learn more

(ID:50046599)

:quality(80)/p7i.vogel.de/wcms/7d/b4/7db4fc5b8cd18e6eb2c864a3c329f177/0129545524v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f5/d2/f5d2bce7c01775fe62d4c6ecebc8c5ba/0129188745v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/38/cb38bf951c0af8a8de423fedce2489d8/0129352475v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b8/13/b8139abf82c98aa04248a4a119d28c13/0129194616v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/e6/eae6aee30071e67a5627027974437134/0129544613v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/40/6040b2e00aef20b4f9d92e8ac9f79c32/0129349725v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/f0/ccf0b07809eaa14635374ad332fd7ea3/0129431466v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8a/d5/8ad5fce4f456b8cd4507598c6c3d92c8/0129546435v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d8/18/d8181873ad07a9b0f77c8ef2d82441cb/0129407783v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f0/d8/f0d82f06ed1b7abb3245dfc4c317cb55/0127949994v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/60/76/607651ea5d461/logo-sq.jpg)

:fill(fff,0)/p7i.vogel.de/companies/62/95/6295c25c8dc1a/schunk-sonosystems-300dpi.png)

:quality(80)/p7i.vogel.de/wcms/91/a9/91a96266933db5bca40352e42f9fba96/0124626305v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/ed/8bed230f3f9de9859f94928062984cec/0124637555v2.jpeg)