CONTROL SYSTEMS Hardware-in-the-loop use cases and advantages

Related Vendors

Hardware-in-the-loop simulation or simply HIL can sound tricky to first-time readers and enthusiasts. This article explains HIL simulations in simple terms with their use cases and benefits. It explains HIL simulations with an EV charging example for better understanding.

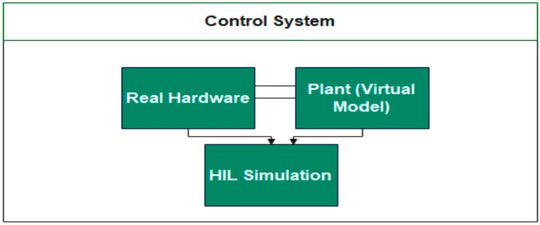

Hardware-in-the-loop simulation integrates actual hardware with virtual models to develop and test real-time complex control systems. Abbreviated as HIL, it determines the response of a device to virtual realistic stimuli. Instead of physical on-site industrial execution, hardware-in-the-loop simulation virtually executes control processes with minimal actual hardware to predict a system’s functionality in advance.

HIL simulation in control systems

A control system consists of four components: sensor, controller, actuator, and plant. A sensor collects the data, a controller controls the plant and an actuator performs the mechanical operation on the plant. The plant is a physical entity that is being controlled or monitored by the control system.

HIL simulation can mimic the behavior of the entire control system process that enables an actuator to control the plant. HIL simulation is mostly run for real hardware like controllers, drivers, and power devices. HIL simulations can test the controller design to validate if it is the best option for you or not.

HIL simulation needs minimal actual hardware for sensors, controllers, and actuators. Virtual models represent plants that showcase the real-world complexities on software. Sometimes sensors, controllers, or actuators can be a simulation due to design requirements and cost.

Hardware-in-the-loop use cases

HIL simulations are a versatile tool for testing and optimizing complex systems, from power electronics to aerospace.

Power Electronics

Power converters, inverters, switches, and switched-mode power supplies use hardware-in-the-loop simulations. Digital signal processors, FPGAs, and another similar technology called DT (Digital Twin) have accelerated HIL simulations in power electronics. As a result, HIL simulations perform power factor correction and improve the efficiency, design, operation, and fault tolerance of a power electronic device.

Power Systems

In the context of electricity, HIL simulations have been implemented in the electrical grid to test the functionality, stability, and fault tolerance capabilities. Such complex simulations consist of thousands of buses, correction devices, and electrical components. Hardware-in-the-loop simulations test the functioning of closely spaced HVDC transmission lines using three-phase transmission models.

Renewable energy

HIL simulations are implemented to improve the efficiency of wind turbines and solar panels. This is because such renewable energy-based systems are heavily dependent upon varying environmental conditions such as wind flow and amount of sunlight. Hardware-in-the-loop simulations implement models based on advanced MPPT techniques (Maximum Power Point Tracking) to improve power generation capabilities.

Motor drivers

Motor drivers used in various industries such as robotics, automotive, and medical equipment are among the widely tested devices through HIL simulations. A real motor driver is integrated into a virtual control system or a plant. HIL simulations evaluate a motor driver’s performance in different conditions such as high speed, torque, temperature, pressure, and various dynamic loads.

Electrification

Manufacturers run hardware-in-the-loop simulations to test the functionality of the hybrid powertrain mechanism of EV vehicles and improve the efficiency of battery technologies. For railways, HIL simulations are run for the usage of regenerative braking systems, railway bridge dampers, and supercapacitors. As a result, HIL simulations become a reason for energy savings and improved efficiency.

Automotive systems

Hardware-in-the-loop simulations are used in the automotive industry to control vehicle dynamics. Virtual plants (vehicles) are extensively used instead of real vehicles. During the development of a power-train system, engineers test the functionality of multiple integrated ECUs (Embedded Controlling Units). Some examples of automotive HIL simulations include engine, windshield wiper, dual-clutch, and steering control tests.

Aviation industry

The aviation industry has been critically using hardware-in-the-loop simulations to optimize fly-by-wire flight controls for decades. Anything related to the aviation industry, including the flight control system in the cockpit, is a high-burden-rate plant. This is because aircraft manufacturing is one of the costliest industries and failure of a flight control system, even at rest, makes companies lose millions of dollars.

Maritime industry

Just like the aviation industry, maritime industries have high-burden-rate plants. In underwater and offshore engineering, real-time hybrid simulators based on data from sea research trials are used. Many European companies are integrating control algorithm tests during mechanical structure design. Some hardware-in-the-loop techniques combine with humans: hardware-and-humans-in-the-loop to plan, design, and test marine equipment.

Example: HIL simulations in an EV charging system

This is an example of an automotive use case of hardware-in-the-loop simulations to explain the technology.

The basic control process

In the EV charging use case, an EV and its charger represent a plant.

Sensor: The sensor records the present data from an EV battery like remaining power, state of charge, voltage, current, and other necessary parameters.

Controller: The controller processes sensor data to determine the execution of the charging process. In simple words, the controller calculates the charging current, voltage, speed, and other characteristics to manage the charging process. The controller sends commands to the actuator.

Actuator: Actuator is a device that takes action to control a plant. In this case, the actuator mechanically executes the charging process based on controller output. An actuator can be a power electronic device such as an IGBT, power MOSFET, or a converter, etc.

:quality(80)/p7i.vogel.de/wcms/50/47/5047818bfeb5d315d1db5c5946dbdeae/0116669487.jpeg)

POWERING THE FUTURE

How electrification is driving the world in 2024

HIL simulations

If you consider implementing hardware-in-the-loop simulation, you can validate the EV charging process just with controllers and power electronic devices. You won’t need a real EV and a charger to validate your test!

Sensor (Virtual): The sensor virtually records and processes computer-simulation-based data. Sometimes sensors can be semi-virtual.

Controller (Real): The controller generates commands based on virtual sensor data. Controller hardware contains code for controller software and control system. There is a proper communication interface between the controller and the components (virtual and real).

Actuator (Real): The actuator executes controller commands on a computer. There are real converters, relays, switches, regulators, etc. Sometimes actuators can be a simulation for ease.

Plant (Virtual): There can be a digital twin model or an entire software of an EV and its charger. It is called a virtual EV model or plant for simplicity.

Hardware-in-the-loop simulations test controller functionality and design through virtual execution of the charging process. The success or failure of the charging process validates the functionality of controllers or associated components.

Benefits of hardware-in-the-loop

Hardware-in-the-loop simulations offer a comprehensive suite of benefits, including accelerated product development, enhanced safety, reduced costs, and the ability to conduct extensive testing under various conditions.

Product lifetime estimation

Hardware-in-the-loop simulations enable product managers to estimate product lifecycle. A device can be tested even before it is manufactured. In addition, the duration of such model-based tests is smaller than actual physical tests. It shortens the time-to-market for the planned product.

Model-based design

The model-based design approach (MBD) integrates virtual models at various stages of the development process. MBD approach designs products based on virtual models. Implementing hardware-in-the-loop simulations tackles increasing design complexity and changing requirements.

Fault analysis

Technically faulty conditions are unsafe and difficult to induce. Inducing faulty conditions for testing can degrade device quality. With the help of HIL simulation, engineers implement software-induced ‘fake’ faulty conditions to test complex functionalities without compromising device performance and safety.

Safety

HIL eliminates the hassle of conducting physical tests in different types of environments such as deserts, snow, underwater, underground, LEO (Low Earth Orbit), and high-altitude regions. It also enables testing the device functionality by virtually creating harsh weather conditions like hurricanes, earthquakes, tsunamis, etc.

Cost-cutting

Hardware-in-the-loop simulations conduct tests for different sets of applications. Design teams run multiple compatibility and functional tests in integrated systems with other devices. HIL simulations reduce the burden rate on plants through virtual testing and optimization of control algorithms.

References

(ID:50158370)

:quality(80)/p7i.vogel.de/wcms/f5/d2/f5d2bce7c01775fe62d4c6ecebc8c5ba/0129188745v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/38/cb38bf951c0af8a8de423fedce2489d8/0129352475v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b8/13/b8139abf82c98aa04248a4a119d28c13/0129194616v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/80/6280da00d591873bf8f0b2a70e5986e0/0129064771v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/40/6040b2e00aef20b4f9d92e8ac9f79c32/0129349725v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f0/d8/f0d82f06ed1b7abb3245dfc4c317cb55/0127949994v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6e/e5/6ee5ad1dc45fd69a5a5718147605850a/0129347492v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/40/7d406bd959b3a9127c33a66157f9030a/0128339184v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/65/22/65223bc58811ced76adbfa7b5615d532/0129061536v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/62/a0/62a0a0de7d56a/aic-europe-logo.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:quality(80)/p7i.vogel.de/wcms/ad/06/ad0628bac08d3d169454a156ad38582f/0122962636v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1f/d4/1fd40d365357b52c36a4c5c668cfc6d3/0123666911v2.jpeg)