BASIC KNOWLEDGE The bridge rectifier explained: Definition, types, and more

Related Vendors

The bridge rectifier is an active component which plays an essential role in power electronics. This article explains the working principles of bridge rectifiers and gives an overview about the different types.

In the realm of power electronics, various components play pivotal roles in ensuring the efficient conversion and management of electrical energy. Among these, the bridge rectifier stands out due to its widespread application and fundamental importance. As we delve deeper into the mechanisms that drive modern electronic systems, it's essential to familiarize ourselves with such active components. In the following sections, we will explore the bridge rectifier, its symbolic representation, and its significance in electrical engineering.

What is a bridge rectifier?

A bridge rectifier - or diode bridge rectifier - is an electronic circuit that converts alternating current (AC) into direct current (DC). This conversion is necessary because many electronic devices only operate on DC, while most power sources provide AC.

You can read about the exact differences between AC and DC power in our article What's the difference between AC and DC power?

Let’s explore the purpose and function of a bridge rectifier with a practical example: Imagine you have a laptop that is powered by an adapter. The power grid in your home supplies AC, but the laptop requires DC. The adapter contains a bridge rectifier that converts the AC into DC. Through this conversion, the bridge rectifier ensures that the laptop receives the necessary constant voltage required for the operation of its internal components.

The bridge rectifier is indispensable in everyday life. Besides power adapters for electronic devices, it is used in numerous other applications such as battery chargers, household appliances, and solar power systems.

Definition Bridge Rectifier

A bridge rectifier is a circuit that converts alternating current (AC) into direct current (DC). Thus, the bridge rectifier is a fundamental and widely used component in electronics, playing a crucial role in the conversion and control of electricity.

How many diodes are used in a bridge rectifier?

When designing or analyzing circuit diagrams, it is important to know which and how many components are used. Since there are different types of rectifiers, the number of diodes is a crucial piece of information to differentiate the various circuits. In practice, the term "bridge rectifier" refers to the classic bridge circuit design using 4 diodes. The conversion of AC to DC is achieved by a specific arrangement of these 4 diodes, each allowing the positive and negative halves of the AC voltage to pass through and convert into a rectified voltage.

The diodes are connected as follows:

- D1 and D2: These two diodes are connected in series, with the anode of D1 connected to the input, while the cathode of D2 is connected to the output.

- D3 and D4: These two diodes are also connected in series but in the opposite direction. The anode of D4 is connected to the input, while the cathode of D3 is connected to the output.

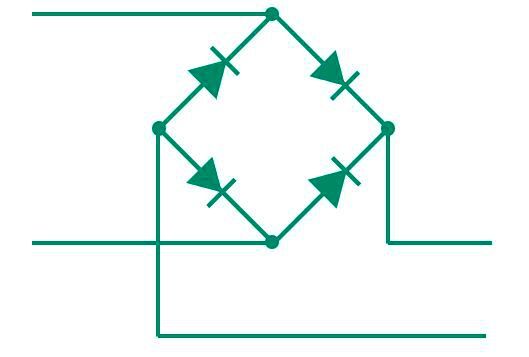

The bridge rectifier symbol

The symbol for a bridge rectifier illustrates the basic configuration of a bridge rectifier. It consists of four diodes arranged in a bridge layout, allowing both halves of the AC waveform to be utilized. This design ensures that the output voltage is always in the same direction, providing a steady DC output. Each diode only conducts during its respective half-cycle, effectively rectifying the AC input. The bridge rectifier symbol is fundamental for understanding how bridge rectifiers operate in electronic circuits, ensuring efficient and reliable power conversion.

:quality(80)/p7i.vogel.de/wcms/6f/d0/6fd0541aec6ab27ea75f4ea3321659ce/86165084v3.jpeg)

RESEARCH AND DEVELOPMENT

A short history of the mercury-arc rectifier

What does a bridge rectifier do?

The operation of a bridge rectifier can be divided into two phases corresponding to the positive and negative halves of the input signal.

Phase 1: Positive half cycle

During the positive half cycle of the AC input, the upper point of the transformer or AC source is positive compared to the lower point. In this phase, diodes D1 and D3 conduct and allow current to pass through, while diodes D2 and D4 are blocked and do not allow current to pass. The current flows through D1, continues through the load (e.g., a resistor), and returns through D3. As a result, the current always flows in the same direction through the load.

Phase 2: Negative half cycle

In the phase of the negative half cycle of the AC input, the polarity reverses: The upper point of the transformer or AC source becomes negative compared to the lower point. Now, diodes D2 and D4 conduct and allow current to pass through, while D1 and D3 remain blocked and do not allow current to pass. The current flows through D4, through the load, and returns through D2. Again, during this phase, the current flows in the same direction through the load as during the positive half cycle.

In both phases, the bridge rectifier ensures that the current always flows in the same direction through the load, enabling the rectification of the AC.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/61/15/61154b39678ff/wp-vorschaubild-nexperia-wp-lg-pb-2021-09-06.png)

Different types and applications of diode bridge rectifiers

There are several types of bridge rectifiers, differing in their design and characteristics, thus offering specific advantages and disadvantages. They are suitable for different applications depending on the requirements for efficiency, voltage, current, and controllability. Here are some of the most common types of bridge rectifiers:

Standard diode bridge rectifier

- Description: The classic form of the bridge rectifier, consisting of four diodes.

- Usage: General applications for converting AC to DC.

- Advantage: Simple design, cost-effective.

Schottky diode bridge rectifier

- Description: Uses Schottky diodes instead of standard diodes.

- Usage: Applications requiring low voltage drops and fast switching times.

- Advantage: Lower forward voltage, faster switching.

- Disadvantage: Lower voltage tolerance, higher cost.

Silicon controlled rectifier (SCR) bridge

- Description: Uses SCRs (thyristors) instead of diodes.

- Usage: Applications requiring controlled rectification, such as motor controls and power supplies.

- Advantage: Allows control of rectification through gating.

- Disadvantage: More complex control required.

Tree-phase bridge rectifier

- Description: A variant of the bridge rectifier that rectifies three phases of AC.

- Usage: Industrial applications using three-phase AC, such as large motor drives.

- Advantage: Smoother DC output due to lower ripple.

- Disadvantage: More complex design, more expensive.

Full-wave bridge rectifier with center tap

- Description: Uses a transformer with a center tap and two diodes.

- Usage: Applications where a center-tapped transformer is available.

- Advantage: Simple design, only two diodes required.

- Disadvantage: Requires a special center-tapped transformer.

MOSFET bridge rectifier

- Description: Uses MOSFETs instead of diodes.

- Usage: High-performance applications where efficiency is crucial.

- Advantage: Very low forward voltage drop, high efficiency.

- Disadvantage: More complex and expensive than conventional diodes.

Synchronous rectifier bridge

- Description: Uses controlled switches such as MOSFETs or IGBTs with control logic.

- Usage: Applications requiring maximum efficiency, such as modern power supplies.

- Advantage: Very high efficiency due to minimal voltage loss.

- Disadvantage: Requires complex control circuitry, higher cost.

Each of these types has specific advantages and is used in different applications depending on the requirements for efficiency, voltage, current, and controllability.

(ID:50115646)

:quality(80)/p7i.vogel.de/wcms/b8/13/b8139abf82c98aa04248a4a119d28c13/0129194616v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/80/6280da00d591873bf8f0b2a70e5986e0/0129064771v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/f6/60f60a22a65f51b4f3603fd1bf64401a/0129067839v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/97/bc97cce107109a551f26fb8076ae1da8/0129190430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/40/7d406bd959b3a9127c33a66157f9030a/0128339184v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/65/22/65223bc58811ced76adbfa7b5615d532/0129061536v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/20/ea20c0beb93f34ab43b28750644bbdca/0128983445v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/0a/b10a283cdf3e5f156781a7273c71a7e0/0129107484v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/b9/62b980cddf5d6/ceramtec.png)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:quality(80)/p7i.vogel.de/wcms/ea/20/ea20c0beb93f34ab43b28750644bbdca/0128983445v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8c/1a/8c1a6f87a2af9653a5df2d5d963915c0/0118206891v2.jpeg)