BASIC KNOWLEDGE Cycloconverters in power electronics

Related Vendors

While buck and boost converters are popular for their mainstream DC-to-DC power conversion, AC-AC converters are less well-known. Cycloconverters are AC-to-AC converters that have been around the world before power transistors and thyristors. They are used in low-speed, high-power motor drivers and several power electronic applications. This article describes cycloconverters and their structure, operation, and applications in power electronics.

Cycloconverters are not new; they were invented sometime in the 1920s. The unique patented technology was first used in the 1930s in Germany to convert a 3-phase 50 Hz system into a single-phase supply of 16.6 Hz for a series of industrial AC traction motors. After the invention of SCRs in the 1960s, cycloconverters were upgraded and used even more.

Cycloconverter definition

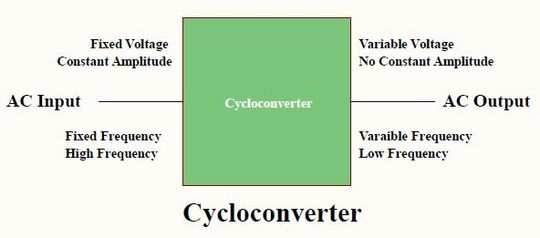

A cycloconverter is a direct AC-to-AC converter with an internal voltage control capability. It converts a high-frequency AC signal to another low-frequency AC signal by controlling the firing angles of interconnected bridges.

Cycloconverter symbol

There is no symbol for a cycloconverter; instead, cycloconverters are represented by connected SCRs and other power components. They contain a half-wave or full-wave bridge rectifier. Generally, cycloconverters use SCRs. However, cycloconverters connected to resistive loads use TRIACs.

1. How are cycloconverters different from conventional AC-AC converters?

Conventional AC-AC converters use an intermediary DC stage. In the first stage, AC-AC converters convert the input AC signal to DC. After this stage, it converts the obtained DC into an AC signal. Finally, the AC signal is fed to the load. Instead of an intermediary DC stage, a cycloconverter uses sets of converters to perform direct AC-to-AC conversion. These converter sets are made from thyristors. Both sets handle positive and negative cycles of the input AC signal.

Along with the converter sets, the cycloconverter implements control mechanisms through microprocessors or digital signal processors. The input AC signal is a high-frequency fixed voltage, but the output AC signal is of low-frequency variable voltage. As cycloconverters do not have a DC link but adjust the frequency for AC-to-AC conversion, they are called frequency changer devices. Cycloconverters (CCVs) are also known as cycloinverters.

:quality(80)/p7i.vogel.de/wcms/d5/26/d526834a1d6fa826198141d3716d88a8/0124344665v2.jpeg)

DC GRIDS

Changing industries: Advancing energy efficiency through DC grids

2. Cycloconverter modes

Based on modes, cycloconverters are of two types: blocking and circulating current mode cycloconverters.

Blocking mode cycloconverters

In blocking mode, cycloconverters, only one converter set remains on during the operation. If one converter set is on, the other remains off, and vice versa. Commercial high-power implementation of cycloconverters takes place through blocking three-phase mode cycloconverters.

Circulating current mode cycloconverters

In circulating mode cycloconverters, both converter sets remain on throughout the operation. They switch between rectifying and inverting modes for effective AC-to-AC conversion. Circulating mode cycloconverters are less commercial and are limited to certain applications.

:quality(80)/p7i.vogel.de/wcms/3b/a1/3ba17e270e28558baef3bca6ee1f8097/0125429353v2.jpeg)

ELECTRIC VEHICLES

LEM launches a new series of DC energy meters for fast and megawatt EV chargers.

3. How does a Cycloconverter work?

There are two types of cycloconverters: single-phase cycloconverters and three-phase cycloconverters. Both of them can be constructed in both blocking and circulating modes.

Single-phase blocking mode cycloconverters

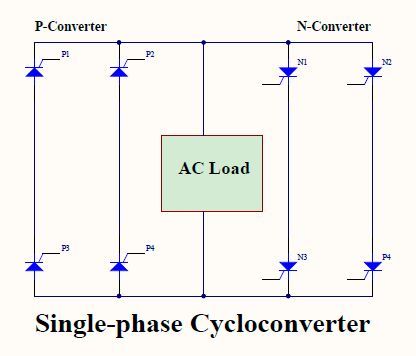

Although rarely used in modern times, single-phase to single-phase cycloconverters were historically in use. This type of cycloconverter uses either a half-wave or full-wave bridge-type dual converter system to implement AC-to-AC conversion. The dual converter design makes the cycloconverter exhibit an inherent capability of bidirectional power flow.

One bridge converter handles the positive half-cycle and the other handles the negative half-cycle of the input AC wave. The bridge converter that handles the positive half-cycle is called the P-converter. Similarly, the bridge converter that handles the negative half-cycle is called the N-converter.

The firing angle is defined as the angle at which the gate terminal is triggered to conduct electricity within an AC cycle. The firing angle of the P-converter is “”. The P-converter is turned on before the N-converter during the operation. The firing angle of the N-converter is “- ”. The difference in the firing angles ensures that each converter conducts during a single cycle— one remains on and the other remains off. It also confirms that voltage levels produced in both cycles are equal and opposite.

During the positive half-cycle of the input AC signal, the P-converter turns on. The N-converter remains off. During the negative half-cycle of the input AC signal, the P-converter turns off and the N-converter turns on. As a result, single-phase to single-phase cycloconverters reduce the input frequency to ⅓ at the output. In simple words, three cycles of the input AC signal get reduced to a single AC cycle at the load.

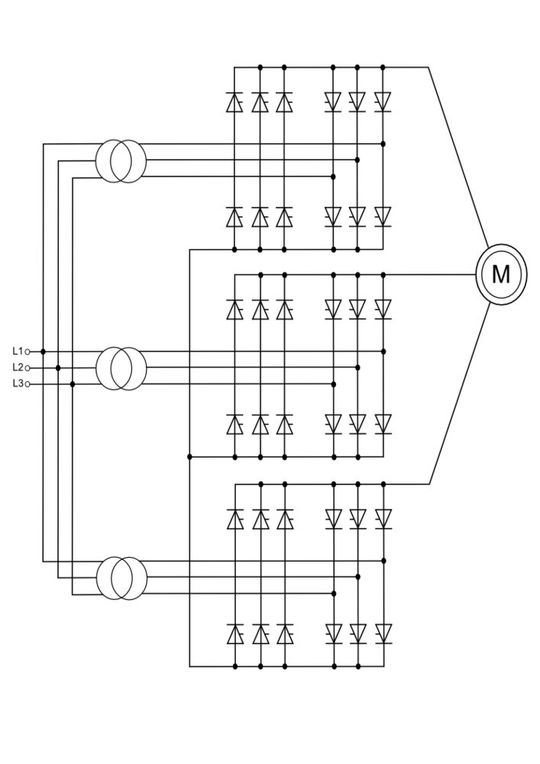

Three-phase blocking mode cycloconverters

Three-phase three-pulse cycloconverters are widely used across the globe. Simply put, a three-phase cycloconverter converts a high-frequency three-phase AC wave to a low-frequency AC wave. The low-frequency AC wave can either be single-phase or three-phase. However, commercial applications use three-phase to three-phase cycloconverters.

In three-phase cycloconverters output voltages stay 120 degrees apart in phase. They can be connected either in a Wye or a Delta configuration, based on their application and ratings. Similar to single-phase to single-phase cycloconverters, three-phase cycloconverters use two sets of converters. One set of converters handles conversion during the positive half-cycle, P-converters, and the other handles conversion during the negative half-cycle, N-converters.

The converters are turned on through a controlled mechanism such that a low-frequency, smooth AC waveform is obtained at the output. In inductive loads, current lags behind voltage. As a result, the current does not stop flowing in one direction even when another set of converters is turned on.

The converter set, which is supposed to operate, sends power back to the source for a short time. The process is called inversion. It allows controlled current flow and aids in voltage matching at the output waveform.

In simple words, three-phase cycloconverters operate in such a “smart way” that the output for the positive half-cycle of the input AC waveform matches the positive half-cycle of the output AC waveform and vice versa.

Three-phase circulating current mode cycloconverters

In three-phase circulating current mode cycloconverters, both P-converter and N-converter sets remain on throughout the operation.

During the positive half-cycle of the input AC signal, the P-converter enters the rectification mode. The N-converter remains in the inversion mode. During the negative half-cycle of the input AC signal, the N-converter enters rectification mode, and the P-converter goes into inversion mode.

The rectification-inversion operation eliminates ripples and does not let voltage lag behind the current. Additionally, a reactor coil, known as IGR (Intergroup Reactor) is placed between the converter sets to limit the unwanted circulating current. It acts like a voltage divider network and offers a highly resistive path to the circulating current.

:quality(80)/p7i.vogel.de/wcms/d2/e6/d2e6e45c06b72b69d6f8e34a31a54baf/0128755281v2.jpeg)

MOTOR EFFINCIENY

Flexible brushed DC motor driver ICs for wide range applications

4. Cycloconverter advantages

- Cycloconverters are not limited by their size, unlike other power devices.

- Cycloconverters do not undergo shocks during startup.

- Cycloconverters exhibit a smooth and variable speed.

- Cycloconverters offer reverse rotation.

- Cycloconverters are naturally commutated power electronic devices. They can naturally turn off, unlike SCRs.

- Cycloconverters offer bidirectional power flow.

- Cycloconverters exhibit low switching losses.

- Cycloconverters exhibit low harmonic and heating losses.

- Cycloconverters provide a nearly sinusoidal output waveform.

- By eliminating a DC stage, cycloconverters save time and power for efficient and quick conversion.

- Cycloconverters require less maintenance.

5. Cycloconverter disadvantages

- Cycloconverters are bulkier and more complicated.

- Cycloconverters operate for a limited frequency range.

- Cycloconverter outputs are not smooth due to oscillations (harmonics). They must use a high number of pulses to obtain a smooth output waveform.

- Cycloconverters lack efficiency.

- Cycloconverters exhibit low power factors.

- Cycloconverters are phase-controlled AC-AC converters. Matrix converters, using PWM-based (Pulse Width Modulation) self-controlled converters, are now used more.

:quality(80)/p7i.vogel.de/wcms/d2/e6/d2e6e45c06b72b69d6f8e34a31a54baf/0128755281v2.jpeg)

MOTOR EFFINCIENY

Flexible brushed DC motor driver ICs for wide range applications

6. Cycloconverter applications

Cycloconverters are still used in a variety of industrial-grade applications. Some of them are listed below.

- Practical converters in AC-AC applications.

- AC series traction motors.

- Low-speed variable voltage variable-frequency ”VVVF” AC drivers.

- Variable-speed constant-frequency “VSCF” systems.

- Auxiliary drivers in power stations.

The industries where cycloconverters are applicable:

- Power electronics— power stations.

- Aircraft systems: 400 Hz power generation.

- Naval ships as propulsion drivers.

- Cement and rolling mills.

- Water pumps and washing machine components.

- Mine hoists and winders.

- Bar mills (Ore processing).

References

(ID:50685122)

:quality(80)/p7i.vogel.de/wcms/bc/97/bc97cce107109a551f26fb8076ae1da8/0129190430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/34/ab3461e7aabc1beab6f2598d09f1d9b4/0128949857v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/92/cd9200bfe196631a5fd7b5b85e25a5a6/0128944352v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/44/4d/444dda9649b5619c79d019c7dc1efcfc/0128974547v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/40/7d406bd959b3a9127c33a66157f9030a/0128339184v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/65/22/65223bc58811ced76adbfa7b5615d532/0129061536v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/20/ea20c0beb93f34ab43b28750644bbdca/0128983445v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/0a/b10a283cdf3e5f156781a7273c71a7e0/0129107484v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:fill(fff,0)/p7i.vogel.de/companies/68/2c/682c3e2e9a195/logotype-rvb.jpeg)

:quality(80)/p7i.vogel.de/wcms/37/64/376449c482d7bc5493c77d057638fe59/0126287882v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/ba/52bad13a953b2f02f0344af930d198a1/0123734944v2.jpeg)