SIC EVOLUTION SiC applications for thermal and electromagnetic management in AI electronics

Related Vendors

Huawei's recent patents are shifting the use of silicon carbide (SiC) from traditional power transistors to critical thermal and electromagnetic management in artificial intelligence and computing hardware. This innovation showcases SiC's exceptional properties, which allow it to handle high voltages and temperatures efficiently. The development underscores the significant role of materials science in advancing electronic technology.

Silicon carbide (SiC) is synonymous with wide-bandgap power electronics due to its remarkable ability to safely manage high voltages, temperatures, and switching frequencies while maintaining low on-resistance. Its intrinsic thermal and mechanical properties extend its value beyond active semiconductor devices, making it indispensable in electric vehicles, energy conversion, and industrial drives. As the industry increasingly adopts SiC, its applications are expanding, revealing the potential of materials science to drive innovation in electronics.

Why SiC excels at managing heat

Unlike silicon or alumina-based ceramics, SiC conducts heat with exceptional efficiency—up to 500 W/m·K in high-purity crystalline form. It also maintains chemical and mechanical stability at elevated temperatures while closely matching the thermal expansion coefficient of semiconductors.

This unique combination allows SiC to serve as both a thermal bridge and a mechanical stabilizer, making it ideal for next-generation chip packaging where heat flux is concentrated in microscopic contact areas. With GPU and AI accelerator power ratings already exceeding 1 kW per device, traditional materials such as silicone grease or aluminum nitride are nearing their limits.

Huawei’s first patent: optimizing thermal conduction

The first of Huawei’s new patents, “Thermal Conductive Composition and Its Preparation Method and Application,” introduces a composite that combines large and small SiC particles in a ratio greater than 3:1, while emphasizing high-sphericity fillers—particles that are nearly spherical, with a shape factor above 0.8.

Sphericity describes how closely each particle’s shape approaches that of a perfect sphere. A value of 1.0 represents an ideal sphere, while irregular milled powders typically fall below 0.7. Huawei’s choice is significant: Such morphology reduces friction and agglomeration during mixing, improves flow during application, and enables tighter packing once the composite cures; that is, when it hardens through a chemical process.

At this microscopic scale, sphericity is typically evaluated using scanning electron microscopy or dynamic image analysis, where particle outlines are digitized and compared statistically with a perfect sphere. Producing SiC particles with sphericity above 0.8 often involves plasma spheroidization or other thermal reflow methods to round sharp edges.

The result is a composite that spreads uniformly and forms a continuous, low-resistance thermal network—ideal for chip packaging materials, underfills, or mold compounds where efficient heat transfer and electrical insulation are equally vital.

:quality(80)/p7i.vogel.de/wcms/b7/ae/b7aef5b0ab72c24edd51f8318d4029c4/0127137768v2.jpeg)

NEW PROJECT

FastLane - Boosting EU material value chain for SiC power electronics

The second patent: dual thermal and electromagnetic protection

Huawei’s second patent, “A Thermal Conductive and Wave-Absorbing Composition and Its Application,” extends the concept of heat management to include the mitigation of electromagnetic interference (EMI).

In this composite, SiC ensures thermal conductivity and mechanical stability, while carbonyl iron—nearly pure, fine-grained iron particles—absorbs and dissipates electromagnetic waves. This absorption occurs via magnetic losses: As iron undergoes hysteresis—the realignment of magnetic domains under oscillating fields—electromagnetic energy is converted into heat.

The particle morphology defines the absorption profile: Spherical iron particles yield uniform, isotropic magnetic behavior, while flaky or plate-like particles broaden the absorption bandwidth into the gigahertz range, the regime most affected by modern high-speed digital and AI computing systems. The resulting dual-function composite simultaneously conducts heat and suppresses EMI, addressing two converging challenges in compact, high-performance electronics such as AI accelerators, 5G/6G communication modules, and advanced system enclosures.

Engineering the particle network

Huawei’s innovation lies in the precise control of particle geometry and distribution. In thermal composites, performance depends not just on the filler’s conductivity but on how efficiently heat transfers across particle-particle and particle-matrix interfaces.

The use of differently sized spherical SiC particles allows smaller ones to fill gaps between larger ones, reducing interfacial resistance and forming a seamless 3D pathway for heat flow.

When magnetic fillers are added, this network gains a second function: dissipating high-frequency electromagnetic waves through magnetic loss mechanisms. The result is a composite engineered for the dual demands of thermal management and EMI suppression in next-generation electronics.

Thermal management as a system-level challenge

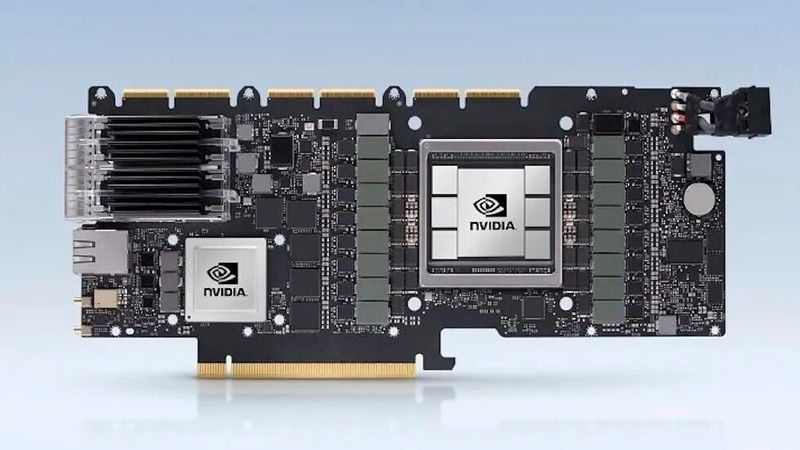

The power consumption of AI hardware demonstrates why such materials are urgently needed. For instance, current Nvidia high-end chips like the H100 can draw up to 700 W, while next-generation chips such as the Blackwell B200 reach up to 1,200 W, with projections suggesting future GPU designs could reach 2,000 W. As transistors scale and chiplets multiply, the heat flux across each square centimeter of silicon increases dramatically.

Conventional interface materials—based on silicone, epoxy, or alumina—can no longer deliver the required thermal conductivity or mechanical compliance. Huawei’s SiC-based composites are designed to bridge this gap, offering improved heat spreading while maintaining automated processability.

In practice, these SiC-based materials could be used as thermal interface layers in high-power AI accelerators, or as EMI-absorbing coatings in 5G and data center modules. The SiC-rich composite efficiently transfers heat from chips to heat spreaders, while the SiC-carbonyl iron hybrid simultaneously absorbs high-frequency electromagnetic noise and conducts heat away from hotspots, enhancing overall system reliability.

:quality(80)/p7i.vogel.de/wcms/8d/e0/8de08e7cf8c954f00d30a4a1894a8294/0126807438v2.jpeg)

COMPARISON

Battle of SiC vs GaN power modules

SiC’s expanding role in the electronics ecosystem

Huawei’s patents also reflect a broader trend: the diversification of SiC applications across the electronics value chain. Beyond Huawei’s composite materials, other industry leaders are exploring SiC in structural roles.

For instance, TSMC has outlined research and roadmap initiatives toward monocrystalline SiC substrates and interposers for next-generation AI processors, as detailed in Power Electronics News.

Huawei, by contrast, leverages SiC as a filler within composite resins to enhance thermal conductivity and EMI control. Together, these approaches position SiC as a platform material bridging chip, package, and system-level design.

Challenges with scaling SiC composites

While Huawei’s patents are technologically promising, several challenges must still be addressed for commercial adoption. Producing high-purity, spherical SiC particles at scale remains costly, and maintaining consistent dispersion within polymer matrices can be complex.

Furthermore, the interfaces between SiC fillers and the surrounding resin play a crucial role in determining overall thermal performance. Surface treatments or coupling agents may be required to optimize adhesion and minimize boundary resistance, the thermal “bottleneck” at the filler-resin interface.

Finally, the integration of magnetic particles introduces mechanical and chemical tradeoffs that must be balanced against thermal gains.

:quality(80)/p7i.vogel.de/wcms/30/1a/301a67e9c76bf2a178b66978f9d0fefd/0127356631v2.jpeg)

POWER SEMICONDUCTORS

Renesas powers 800 V DC AI data center architecture

Implications for AI-era electronics

As the AI industry shifts toward ever-higher power densities and multi-chip architectures, materials innovation is becoming as critical as semiconductor scaling once was. The success of future GPUs and accelerators will depend not only on transistor speed but on how efficiently heat and electromagnetic energy are managed.

Huawei’s SiC-based composites offer a pathway toward this new equilibrium, where thermal conductivity, electromagnetic shielding, and process compatibility can coexist in a single engineered material. Such advances could redefine how packaging engineers approach heat dissipation, moving from passive cooling strategies to material-level thermal design.

A new dimension for SiC

Speculations have surfaced online suggesting that these composites were specifically designed for Huawei’s upcoming flagship smartphone line, the Mate 80. However, the patents emphasize attributes more commonly required in high-power or EMI-sensitive components, the kind frequently used in AI data centers and high-performance computing.

In any case, Huawei’s latest patents signal a strategic expansion of SiC’s role in electronics. By optimizing particle morphology, purity, and hybrid composition, Huawei appears to be pioneering a class of materials that not only conduct electricity but also conduct and control heat when dispersed. This convergence of materials science and electronic design underscores a broader truth: In the next generation of high-performance systems, thermal engineering is electronic engineering, and SiC is poised to be at the heart of both.

(ID:50643142)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:fill(fff,0)/p7i.vogel.de/companies/66/8b/668becd1c07eb/dowa-logo-word--1-.jpeg)

:quality(80)/p7i.vogel.de/wcms/37/64/376449c482d7bc5493c77d057638fe59/0126287882v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/af/9aafa5ad3d3d900a6e22adf6d06a9bf5/0126877798v2.jpeg)