SEMICONDUCTOR TECHNOLOGY ROHM Launches 2-in-1 SiC Molded Module “DOT-247”

Sponsored by

ROHM has developed the "DOT-247," a 2-in-1 SiC molded module (SCZ40xxDTx, SCZ40xxKTx), ideal for industrial applications such as PV inverters, UPS systems, and semiconductor relays. The module retains the versatility of the widely adopted "TO-247" package while achieving high design flexibility and power density.

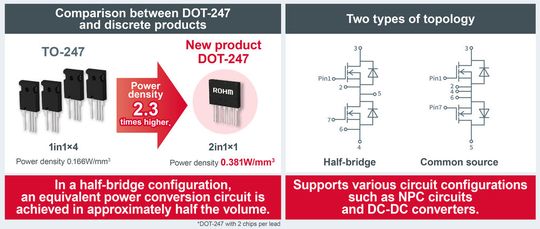

The DOT-247 features a combined structure consisting of two TO-247 packages. This design enables the use of large chips, which were structurally difficult to accommodate in the TO-247 package, and achieves low on-resistance through an unique internal structure. Additionally, through optimized package structure, thermal resistance has been reduced by approximately 15% and inductance by approximately 50% compared to the TO-247. This enables a power density 2.3 times higher than the TO-247 in a half-bridge configuration – achieving the same power conversion circuit in approximately half the volume.

The new products featuring the DOT-247 package are available in two topologies: half-bridge and common-source. Currently, two-level inverters are the mainstream in PV inverters, but there is growing demand for multi-level circuits such as three-level NPC, three-level T-NPC, and five-level ANPC to meet the need for higher voltages. In the switching sections of these circuits, topologies such as half-bridge and common-source are mixed – making custom products necessary in many cases when using conventional SiC modules.

To address this challenge, ROHM has developed each of these two topologies – the smallest building blocks of multi-level circuits – into a 2-in-1 module. This enables flexibility to support various configurations such as NPC circuits and DC-DC converters, while significantly reducing the number of components and mounting area, and achieving circuit miniaturization compared to discrete components.

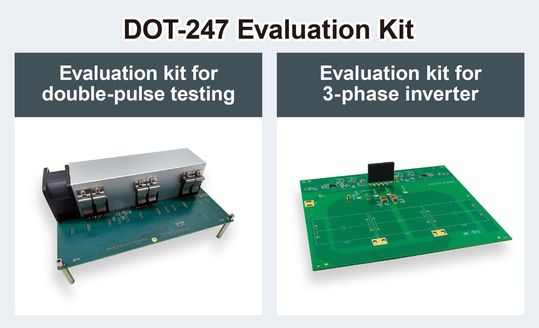

Evaluation boards will also be made available progressively to facilitate evaluation during application design. For more information, please contact a sales representative or visit the contact page on ROHM’s website.

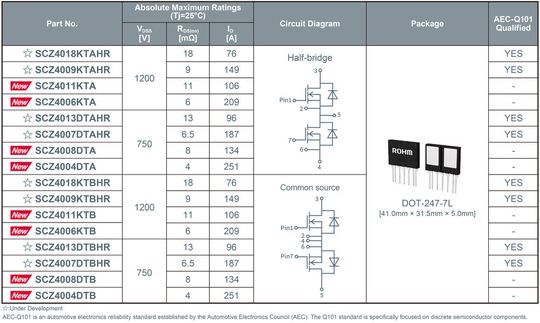

Product Lineup

Application Examples

PV inverters, semiconductor relays, UPS (uninterruptible power supply), ePTO, and boost converters for FCVs (fuel cell vehicles).

AI servers (eFuse), EV charging stations, etc.

Sales Information

Availability: ROHM construct mass production (September 2025)

Products compliant with the automotive reliability standard AEC-Q101 are scheduled to begin sample shipments in October 2025.

Comprehensive Support

ROHM is committed to providing application-level support, including the use of in-house motor testing equipment. A variety of supporting materials are also offered, such as simulations and thermal designs that enable quick evaluation and adoption of DOT-247 products. An evaluation kit for double-pulse testing is already available, allowing immediate testing, while an evaluation kit for 3-phase inverters is currently under preparation, with reference designs scheduled to be released from November 2025.

About the DOT-247 design models

- SPICE models: Available on the product web pages for each part number

- LTspice® models: Scheduled to be available for three-level NPC from October 2025 on the web pages

- LTspice® is a registered trademark of Analog Devices, Inc. When using third-party trademarks, please adhere to the usage guidelines specified by the rights holder.

For details, please contact a sales representative or visit the contact page on ROHM’s website.

EcoSiCTM Brand

EcoSiCTM is a brand of devices that utilize silicon carbide (SiC), which is attracting attention in the power device field for performance that surpasses silicon (Si). ROHM independently develops technologies essential for the evolution of SiC, from wafer fabrication and production processes to packaging, and quality control methods. At the same time, we have established an integrated production system throughout the manufacturing process, solidifying our position as a leading SiC supplier.

EcoSiCTM is a trademark or registered trademark of ROHM Co., Ltd.

(ID:50552431)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:quality(80)/p7i.vogel.de/wcms/28/e1/28e1145550d60f2d84ac63bdf2bf00d6/0124354853v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/18/38/18388bb688987616334178b455d61e94/0127093649v4.jpeg)