ELECTROMOBILITY ROHM Develops New High Power Density SiC Power Modules

Sponsored by

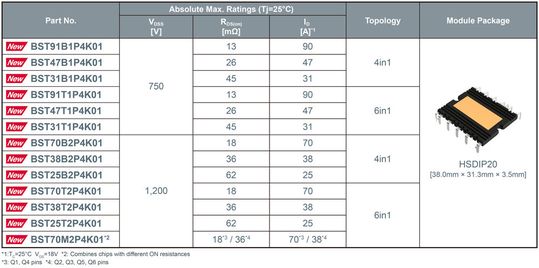

ROHM has developed the new 4-in-1 and 6-in-1 SiC molded modules in the HSDIP20 package optimized for PFC and LLC converters in onboard chargers (OBC) for xEVs (electric vehicles). The lineup includes six models rated at 750V (BSTxxx1P4K01) and seven products rated at 1200V (BSTxxx2P4K01). All basic circuits required for power conversion in various high-power applications are integrated into a compact module package, reducing the design workload for manufacturers and enabling the miniaturization of power conversion circuits in OBCs and other applications.

In recent years, the rapid electrification of cars is driving efforts to achieve a decarbonized society. Electric vehicles are seeing higher battery voltages to extend the cruising range and improve charging speed, creating a demand for higher output from OBCs and DC-DC converters. At the same time, there is an increasing need in the market for greater miniaturization and lighter weight for these applications, requiring technological breakthroughs to improve power density - a key factor - while enhancing heat dissipation characteristics that could otherwise hinder progress. ROHM’s HSDIP20 package addresses these technical challenges that were previously becoming difficult to overcome with discrete configurations, contributing to both higher output and the downsizing of electric powertrains.

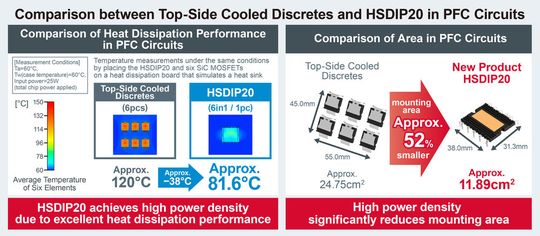

The HSDIP20 features an insulating substrate with excellent heat dissipation properties that suppresses the chip temperature rise even during high power operation. When comparing a typical OBC PFC circuit utilizing six discrete SiC MOSFETs with top-side heat dissipation to ROHM’s 6-in-1 module under the same conditions, the HSDIP20 package was verified to be approx. 38°C cooler (at 25W operation). This high heat dissipation performance supports high currents even in a compact package, achieving industry-leading power density more than three times higher than top-side cooled discretes and over 1.4 times that of similar DIP type modules. As a result, in the PFC circuit mentioned above, the HSDIP20 can reduce mounting area by approx. 52% compared to top-side cooled discrete configurations, greatly contributing to the miniaturization of power conversion circuits in applications such as OBCs.

Going forward, ROHM will continue to advance the development of SiC modules that balance miniaturization with high efficiency while also focusing on the development of automotive SiC IPMs that provide higher reliability in a smaller form factor.

Application Examples

Power conversion circuits like PFC and LLC converters are commonly used in the primary side circuits of industrial equipment, allowing the HSDIP20 to also contribute to the miniaturization of applications in both the industrial and consumer electronics fields.

- Automotive systems: Onboard chargers, electric compressors and more.

- Industrial equipment: EV charging stations, V2X systems, AC servos, server power supplies, PV inverters, power conditioners, etc.

Sales Information

Availability: OEM quantities (April 2025)

Supporting Information

ROHM is committed to providing application-level support, including the use of in-house motor testing equipment. A variety of supporting materials are also offered such as simulations and thermal designs that enable quick evaluation and adoption of HSDIP20 products. Two evaluation kits are available as well, one for double-pulse testing and the other for 3-phase full bridge applications, enabling evaluation under close to actual circuit conditions.

For more information, please contact a sales representative or visit the contact page on ROHM’s website.

EcoSiC™ Brand

EcoSiCTM is a brand of devices that utilize silicon carbide, which is attracting attention in the power device field for performance that surpasses silicon. ROHM independently develops technologies essential for the advancement of SiC, from wafer fabrication and production processes to packaging, and quality control methods. At the same time, we have established an integrated production system throughout the manufacturing process, solidifying our position as a leading SiC supplier.

EcoSICTM is a trademark or registered trademark of ROHM Co., Ltd.

* ROHM April 24, 2025 study

(ID:50400021)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:quality(80)/p7i.vogel.de/wcms/ce/7a/ce7a9c4e7281c4fc316fc7bcbe0c269b/0126790865v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/3f/ae3fb1c470e07a65cca9a6d03a0d28e8/0128385730v2.jpeg)