ELECTROMOBILITY Power modules in electric vehicles

Related Vendors

Most applications require efficient power conversion. A single IGBT won't do justice, but a group of IGBTs would! You can call these groups of power devices “power modules”. Power modules are increasingly becoming applicable in various industries such as renewables, electric vehicles, industrial automation, rail transportation, aerospace, data centres, telecommunications, and many more.

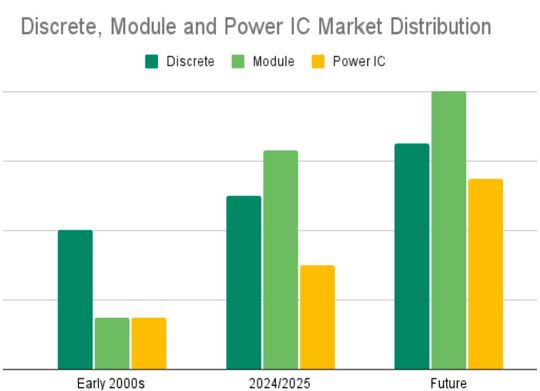

Power devices are available as discrete components, integrated circuits (chips), and modules. Discrete power components are the oldest form of power devices. They are big enough to be used in any application. Modern electronics rely on miniaturization. Hence, the industry went on to invent power modules and power chips.

Historically, a single BJT was just not enough. The current gain of a single BJT is too low and insignificant in real-life applications. As a solution, engineers combined two BJTs, calling them a “Darlington pair”, to maximize the current gain. Based on this approach, power modules were invented in the 90s.

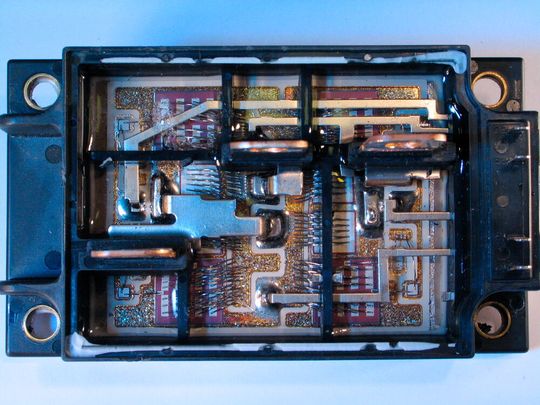

A power module contains several power semiconductors, such as power transistors, diodes, and thyristors, connected in the form of dies. Dies are semiconducting materials consisting of circuit designs. Circuit elements, including inductors, capacitors, resistors, and many more, support these power semiconductor dies. Power modules are innovative enough to provide proper electrical and thermal insulation.

No, the power module structure does not contain discrete power transistors, diodes, and thyristors connected, because the design would be bulky and impractical! The diagram below explains the same.

As mentioned above, discrete devices have been ruling the power industry. In modern times, discrete devices and power modules are on par. Due to electric vehicles and other rising applications, power modules are becoming increasingly popular. Power modules are going to dominate the power industry in the future.

Role of power modules in electric vehicles

Power modules in the context of EVs are known as automotive modules. Both electric vehicles and charging stations use power modules. In EVs, power modules are present in complicated electronic systems.

Charging stations also use power modules to charge a large number of electric vehicles together and faster. Through both use cases, power modules handle efficient power conversion and regulation in the automotive industry.

From battery to wheels: Motor control unit

The motor control unit (MCU) is like the brain of an electric vehicle that controls the motor, which enables it to move or stop. MCU consists of an inverter and control electronics. The inverter ensures efficient and precise control of motor speed and torque generation. Power modules are used as inverters in MCUs.

EV batteries, known as traction batteries, store power in DC, rather than AC. It is a well-known fact in the electronics industry that all motors run on AC. As a result, an inverter must be present to deliver this power to the motor.

Power modules convert DC from traction batteries to three-phase AC power. IGBT and SiC MOSFET power modules handle hundreds of volts, such as standard 400 V and between 800-1200 V for the latest EV architectures. For example, Tesla cars use SiC MOSFET power modules.

When the motor gets three-phase AC power, it creates a rotating magnetic field. This magnetic field pulls on the rotor, producing torque– mechanical movement. A transmissible unit is present in the EV, which transfers this movement to the wheel. Hence, power modules are critical for electric vehicle movement!

:quality(80)/p7i.vogel.de/wcms/f9/29/f92903189bb36304a6bbc7ca5ba8e3fc/0117522391.jpeg)

POWER ELECTRONICS

Inverter vs converter: What's the difference?

Recovering the energy loss: Regenerative braking system

When conventional cars slow down or stop due to braking, kinetic energy is lost as heat. In EVs, designers aim to preserve kinetic energy. The desire to run electric vehicles on roads for longer periods than conventional cars drives the need for energy recovery.

Modern EVs are based on regenerative braking. When an electric vehicle slows down or stops due to braking, the MCU signals the motor to resist the change. The motor behaves like a generator, producing AC power. The inverter takes this AC and converts it into DC for traction batteries.

Powering the battery: EV charger

Just like the door of the small fuel tank gate of conventional cars, electric vehicles contain a charging port. The external source, which aims to charge the EV, must be connected to the charging port. The external source can be the grid or a charging station.

It is important to note that traction batteries in EVs run on DC power. The grid voltage is AC. Electric vehicles contain an in-house power converter known as an onboard charger. It converts incoming AC to DC power to charge electric vehicle traction batteries.

The process of converting AC to DC is called rectification. EVs use power modules to carry out rectification. Power modules like IGBTs or SiC MOSFETs offer bidirectional power conversion, faster charging solutions, and heat regulation. SiC modules are getting popular due to lightweight designs.

The “boosted” support

As mentioned above, premium electric vehicles rely on 800 V to 1200 V for faster charging and extended range. Legacy charging stations handle 400 V. A booster stage containing DC-DC power modules steps up the DC bus level voltage from 400 V to 800 V or 1200 V, based on the requirement.

Auxiliary systems are not critical for EV movement. They incorporate infotainment systems, lightning, climate control, and BMS (Battery Management Systems). They need a stable DC power supply to function. Power modules as DC-DC converters deliver the required DC power from the traction battery to auxiliaries.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

Smarter charging

Modern charging infrastructure aims to offer scalable and fast charging solutions, comparable to gas stations. Smart charging units are app-connected for remote management and can handle kilowatts of power to support 1-12 charging plugs.

In general, charging stations provide AC power output. Modern charging infrastructure uses SiC and GaN-based power modules to convert AC to high-power DC. As a result, they might be able to charge electric vehicles quickly.

The potential

The global automotive power module market is valued at USD7.86 billion. It is expected to hit USD25.14 billion in 2032, at one of the highest CAGRs of 14.3 % among various electronic industries. Both battery electric vehicles (Fully EVs) and hybrid power trains (Hybrid EVs) use power modules.

Due to their effective involvement in power conversion and regulation, power modules are subject to significant stress. Environmental factors, heat, and mechanical wear and tear also play a big role. Hence, automotive modules must be reliable and have a long lifespan.

Modern power modules are made from wideband semiconductors like SiC. Such semiconducting materials offer faster charging, better power handling capabilities, higher energy density, and longer lifespan. At present, SiC IGBTs and SiC MOSFETs rule the automotive power module market.

References

(ID:50553208)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:quality(80)/p7i.vogel.de/wcms/0e/13/0e132310ca94e4d27cfc167cbcf567f9/0128546543v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/e1/28e1145550d60f2d84ac63bdf2bf00d6/0124354853v2.jpeg)