SEMICONDUCTOR TECHNOLOGY onsemi unveils vertical GaN semiconductors: a breakthrough for AI and electrification

Related Vendors

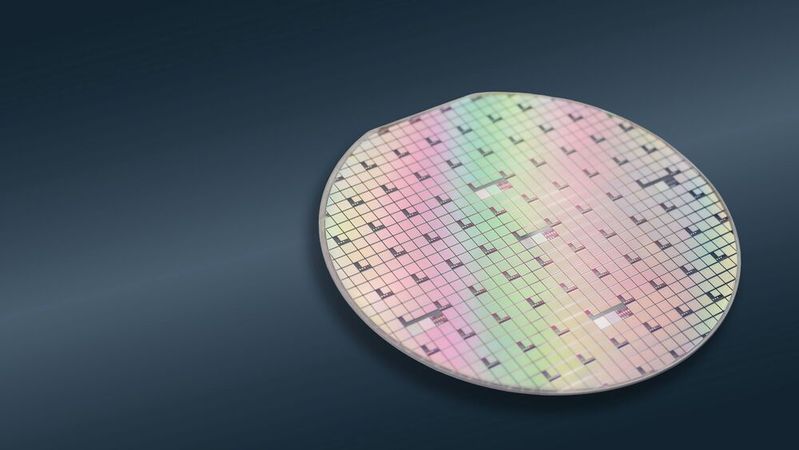

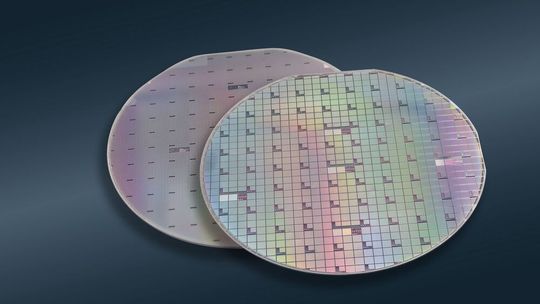

Onsemi has introduced vertical gallium nitride (vGaN) power semiconductors, setting a new benchmark for power density, efficiency and ruggedness for these applications. These GaN-on-GaN power semiconductors conduct current vertically through the compound semiconductor, enabling higher operating voltages and faster switching frequencies, leading to energy savings to deliver smaller and lighter systems.

Onsemi’s vGaN technology is a breakthrough power semiconductor technology that sets a new benchmark for efficiency, power density and ruggedness for the age of AI and electrification. Developed and manufactured at onsemi’s fab in Syracuse, NY, onsemi holds over 130 global patents covering a range of fundamental process, device design, manufacturing and systems innovations for vertical GaN technology.

“Vertical GaN is a game-changer for the industry and cements onsemi’s leadership in energy efficiency and innovation. As electrification and AI reshape industries, efficiency has become the new benchmark that defines the measure of progress. The addition of vertical GaN to our power portfolio gives our customers the ultimate toolkit to deliver unmatched performance. With this breakthrough, onsemi is defining the future where energy efficiency and power density are the currency of competitiveness.” says Dinesh Ramanathan, Senior Vice President of Corporate Strategy, onsemi.

Why it Matters: The world is entering a new era where energy is the defining constraint on technological progress. From electric vehicles and renewable energy to AI data centers that now consume more power than some cities, the demand for electricity is rising faster than our ability to generate and deliver it efficiently. Every watt saved now counts.

:quality(80)/p7i.vogel.de/wcms/e1/03/e1037c01bbe9722bf96e292e0010bbbe/0125512618v2.jpeg)

GALLIUM NITRIDE

What is a GaN charger and is it safe for use?

onsemi's vGaN technology is designed to handle high voltages in a monolithic die – 1,200 volts and beyond – switching high currents at high frequency with superior efficiency. High end power systems built with this technology can reduce losses by almost 50% and by operating at higher frequencies can also reduce the size, including passives like capacitors and inductors by a similar amount. Additionally, compared to commercially available lateral GaN, vGaN devices are approximately three times smaller. This makes onsemi’s vGaN ideal for critical high-power applications where power density, thermal performance and reliability are paramount, including:

- AI Data Centers: Reduced component counts, increased power density for 800V DC-DC converters for AI compute systems to greatly improve cost per rack

- Electric Vehicles: Smaller, lighter and more efficient inverters, for increased EV range

- Charging Infrastructure:Faster, smaller, more rugged chargers

- Renewable Energy:Higher voltage handling, reduced energy losses for solar and wind inverters

- Energy Storage Systems (ESS): Fast, efficient, high-density bidirectional power for battery converters and microgrids

- Industrial Automation: Smaller, cooler, higher efficiency motor drives and robotics

- Aerospace, Defense and Security: Higher performance, enhanced ruggedness and more compact designs

How It Works:

Most commercially available GaN devices are built on a substrate that is not GaN – primarily silicon or sapphire. For very high voltage devices, onsemi’s vGaN uses a GaN-on-GaN technology that allows current to flow vertically through the chip rather than across its surface. This design delivers higher power density, greater thermal stability and robust performance under extreme conditions. With these benefits, vGaN leapfrogs both GaN-on-silicon and GaN-on-sapphire devices to deliver higher voltage capability, higher switching frequency, superior reliability and enhanced ruggedness. This enables the development of smaller, lighter and more efficient power systems with reduced cooling requirements and lower overall system cost. Key benefits include:

- Higher Power Density: Vertical GaN can handle higher voltages and larger currents in smaller footprints

- Greater Efficiency: Cuts energy losses during power conversion, reducing heat and lowering cooling costs

- Compact Systems: Higher switching frequency reduces the size of passive components such as capacitors and inductors

Availability:

Sampling now to early access customers

(ID:50612126)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:quality(80)/p7i.vogel.de/wcms/7b/a0/7ba0a5453a2ba24e3edc852527ed7f27/0128662544v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0e/13/0e132310ca94e4d27cfc167cbcf567f9/0128546543v2.jpeg)