AEROSPACE Multi-level power inverters in aircraft

Related Vendors

Beyond electricity stations and factories, the science of power electronics is also applicable to the aerospace industry and rocket technology. Aeroplanes are heavily equipped with reliable electronics and machines, which enable them to fly safely. There is no room for error in their systems. Aeroplanes use power electronic devices to handle power generation, conversion, and delivery onboard. The article explains multi-level inverters in aircraft.

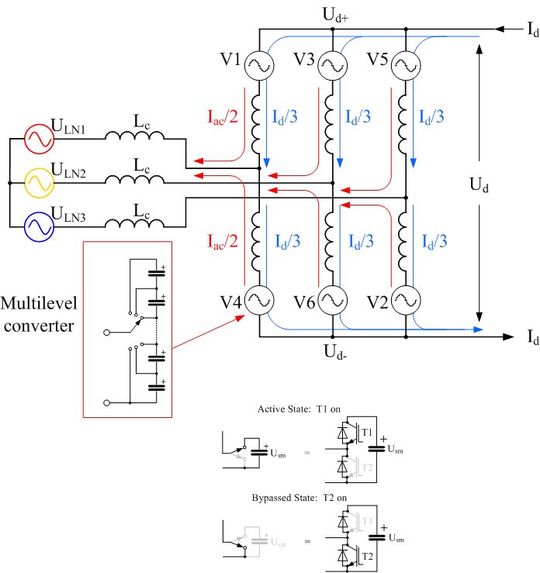

Multi-level converters (MLC) and multi-level inverters (MLI) are applicable in high-voltage and high-power applications. These devices can generate higher voltage levels from low-rated inputs.

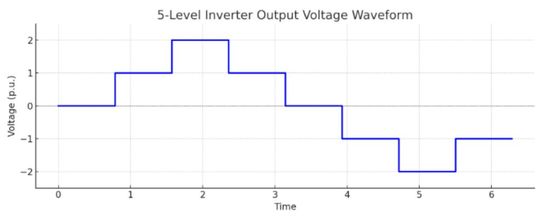

The output of multi-level inverters is in the form of steps (levels), rather than switching directly between high and low voltages. Simply put, multi-level inverter output is a step-like AC voltage. Multi-level inverters have a complex structure with many switches. Depending upon their topologies, they use a different number of switches per phase. Multi-level inverters show low total harmonic distortion and solve high di/dt problems in the inverter output voltage.

The “level” in multi-level inverters shows the number of distinct output voltage levels they can produce. For example, a 3-level MLI can produce - V, 0V, and +V at the output. It means that the output voltage of a 3-level multi-level inverter fluctuates between -V and +V. A 5-level MLI can produce -2V, -V, 0V, +V, and +2V at the output. The output voltage of 5-level multi-inverters varies between -2V and +2V.

Multi-level inverter applications

Multi-level inverters are applicable in various industrial applications listed below.

- HVDC lines.

- Flexible AC transmission systems.

- Induction motor control

- Sinusoidal current rectifiers.

- Active filters.

- Motor drivers.

- Electric vehicle drivers.

- Smart grids.

- Power factor compensator networks.

- Static VAR compensators.

- Frequency link systems.

One of the latest applications explores their potential in aerospace engineering.

Why is the selection of components critical in aircraft?

In flights, environmental variations like vibrations (turbulence), smoke due to burning, cosmic radiation of neutrons, and single-event effects exist. Temperature and pressure changes during take-off, climb, mid-air, descent, and landing times affect the operation of electronic components.

These environmental effects lead to an accelerated failure rate of power electronic components. An optimal solution is to run simulations during propulsion system design. It helps in estimating the component fatigue and lifespan before selection and actual implementation.

What matters most in aircraft?

Legacy semiconducting components used in aircraft are based on a 100 Hz frequency. Excess cabling increases the chances of mechanical wear and tear and aircraft weight. As a result, these chain reactions would trigger higher fuel consumption. In aircraft, reliability factors predominate over weight and efficiency. Aircraft electronics adhere to strict EMC requirements.

Rather than silicon, wide bandgap semiconductors like SiC (Silicon Carbide) and GaN (Gallium Nitride) are preferred in aircraft. The advantage of wide bandgap semiconductors is that they exhibit faster switching times and high power density, meaning they offer higher power in compact designs. However, WBG semiconductors generate more EMI.

:quality(80)/p7i.vogel.de/wcms/f9/29/f92903189bb36304a6bbc7ca5ba8e3fc/0117522391.jpeg)

POWER ELECTRONICS

Inverter vs converter: What's the difference?

Multi-level inverters in aircraft

CSI (Current Source Inverters) and VSI (Voltage Source Inverters) are popular inverters applicable in many industries. As aircraft rely on high voltage and power, single inverters are unlikely to perform efficiently. They cannot withstand high voltage stress, leading to distorted outputs. Multi-level inverters are capable of operating in such challenges. They offer the following benefits in aircraft systems.

- High power and voltage handling capacity.

- Lightweight design.

- Lower voltage per component.

- Smooth voltage output.

- Low total harmonic distortion.

- Low electromagnetic interference.

- High levels of scalability.

- High efficiency.

- Improved power density and optimized cooling.

- Modular and fault-tolerant capabilities.

There are several multi-level inverter topologies, such as diode-clamped, flying capacitor, cascaded H-bridge, parallel phase, hybrid (mixed level), hybrid asymmetric, and many others.

Cascaded H-bridge multi-level inverter

A cascaded H-bridge multi-level inverter consists of an H-bridge cell, which is a single-phase inverter. Multiple H-cells are connected in series on the AC side. Each H-cell has its own DC supply. In general, the secondary winding of the transformer allows it to extract power from the supply.

In aircraft, battery-powered DC supplies can be used. Cascaded H-bridge multi-level inverters offer high power quality, scalable voltage levels, and simpler modular control. The only drawback is the presence of a large number of isolated DC sources.

When compared to other multi-level inverter topologies, cascaded H-bridge multi-level inverters achieve the same output voltage levels with fewer components. It means that they are lightweight, suitable for aircraft systems.

Flying capacitor multi-level inverter

Flying capacitor multi-level inverters (FC-MLIs) use capacitors as clamping devices. A clamper shifts the DC level of a signal either in positive or negative peaks. Unlike the cascaded H-bridge topology, the flying capacitor MLI uses only one DC source.

Flying capacitor multi-level inverters are applicable in motor drivers of propulsion systems. They require a large number of capacitors that need pre-charging for operation. The capacitors are difficult to balance, making the overall inverter control difficult.

Diode-clamped multi-level inverter

Diode-clamped multi-level inverters (DC-MLIs) are also known as neutral-point clamped inverters. They use multiple switches like IGBTs (Insulated Bipolar Junction Transistors), clamping diodes, and DC bus capacitors. Different capacitor sections split the DC bus. Switches and clamping diodes connect intermediate capacitor voltages to output phases, generating multiple voltages at the output.

Diode-clamped multi-level inverters offer low total harmonic distortion and dv/dt ratings, without the need for additional filters. The control mechanism is also simple. However, the design is complex due to the high number of clamping diodes. Also, efficiency can be reduced due to the fluctuating nature of the DC bus voltage. DC-MLIs perform better in medium-power industrial applications.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

Hybrid multi-level inverter

Hybrid multi-level inverters are designed to achieve better results in aircraft systems. One multi-inverter topology performs the main bulk power conversion, and another improves the nature of the output waveform.

The combination of flying capacitor and diode-clamped multi-inverters, commonly called FC-NPC MLI, shows higher efficiency and better harmonic performance through fewer inverter cells in aircraft systems.

Another research shows that the ANPC (Active Neutral Point Clamped) multi-level inverter solves voltage balancing and switching loss issues in aircraft systems.

PWM-based multi-level inverter

The problem with multi-level inverters is the nature of the output waveform. Step-based output voltage can mimic a sinusoidal waveform but is less pure. Some harmonic distortion is still present. The PWM (Pulse Width Modulation) technique in multi-level inverters enables the extraction of a sinusoidal output easily.

Fractional sinusoidal pulse width modulation (FSPWN) enables high-frequency AC generation in aircraft systems. They use fewer power switches compared to other multi-level inverter topologies. Due to skin effect, the design tends to reduce cable weight. FSPWN MLIs offer precise control over output waveforms at higher frequencies from 400 Hz to 1 kHz.

The 400 Hz design is operational in aircraft. The high-frequency design is expected to decrease the aircraft’s weight by more than 10 kilograms. A recent study has found another PWM method, called windowed pulse width modulation (WPWM), to be useful in reducing switching losses. The switching happens in “windows” of time to lower losses.

Conclusion

The concept of MEA (More Electric Aircraft) in the aerospace industry drives the need for power electronic systems to deliver the required power to each component in the aircraft. The shift is expected to fully electrify propulsion systems! An actuator is a system that converts an electrical, pneumatic, or hydraulic quantity into mechanical motion.

Electric actuators are replacing legacy hydraulic and pneumatic actuators in aircraft. Inverter-led motors power electric actuators– Electromechanical Actuators (EMAs) and Electrohydrostatic Actuators (EHAs). Instead of standard inverters, multi-level inverters are considered a good candidate in the distributed drive systems of an aircraft.

References

(ID:50541566)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:quality(80)/p7i.vogel.de/wcms/8c/1a/8c1a6f87a2af9653a5df2d5d963915c0/0118206891v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/96/ad967e992a13bd0359fef58cccd47048/0125441002v2.jpeg)