RENEABLE ENERGY Hydrogen in enegry storage

Related Vendors

Hydrogen, the noble gas with atomic number 1, makes up most of the Sun to support life on Earth. Initially considered only for nuclear fusion and fission, the most abundant gas in the universe, hydrogen, is not just a fuel but is emerging as a medium for bidirectional energy storage. Similar to a Li-ion battery storing electrons in its chemicals, hydrogen stores electricity in the form of strong H2 bonds.

Hydrogen, the lightest and most abundant element in the universe, is not only a key component of the Sun and essential for life on Earth, but it is also emerging as a versatile medium for energy storage, capable of storing electricity from renewable sources in chemical bonds and releasing it on demand through fuel cells or combustion processes.

How does hydrogen enter energy storage systems?

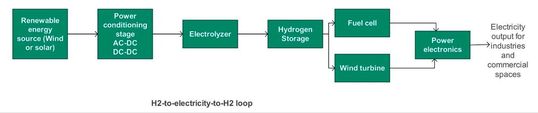

Hydrogen is a part of energy storage systems through a loop. The hydrogen to electricity to hydrogen loop, styled as H2-to-electricity-to-H2, is a long-term energy storage plan that uses energy, often from renewable sources, to produce hydrogen, store it, and later convert it to produce electricity. The process starts when power electronic devices take renewable electricity from solar cells or wind mills.

The power electronics devices feed an electrolyzer, which consists of two electrodes separated by an electrolyte. Common electrolyzers include AEL (Alkaline Electrolyzer), PEM (Proton Exchange Membrane), AEM (Anion Exchange Membrane), and SOEC (Solid Oxide Electrolyzer Cell). An electrolyzer uses electricity from these renewable sources to perform electrolysis, the process in which water molecules (H2O) split into two gases - hydrogen (H2) and oxygen (O2).

Both gases are collected separately to prevent mixing. The resulting hydrogen gas is 99.999% pure, often called “green hydrogen.” Hydrogen is then compressed, liquefied, and stored for extended periods, such as months, in steel tanks, pipelines, salt caverns, or energy storage devices. The same stored hydrogen is later fed into the fuel cell or hydrogen turbines to produce electricity, with water and heat as byproducts.

The H2-to-electricity-to-H2 loop shows the bidirectional nature of hydrogen. In the forward loop, the first stage, electricity is converted into hydrogen for energy storage. With the help of fuel cells or turbines, hydrogen is again converted into electricity and water. The energy recovery happens at the final stage of the loop. Water, again, undergoes electrolysis to start the process all over.

:quality(80)/p7i.vogel.de/wcms/8b/2c/8b2c91c5b3e77593bf4cc41c6c37193a/0122097482v2.jpeg)

EXPERT OPINION

Decarbonizing with H2 needs decarbonizing H2 first

Where does power electronics fit in the H2 loop?

About 50-55 kWh of electricity can produce 1 kg of hydrogen. Power electronics come into play during the very first stage of the hydrogen to electricity to hydrogen loop. The job of a power electronic converter is to take electricity from solar or wind plants for the electrolyzer. H2 loops rely on low-voltage, high-current systems that require multiple DC voltage levels with respect to renewable sources.

The efficiency of the different electrolyzers varies in practice. PEM electrolyzers are 50-83% efficient, AEL are 50-78%, AEM are 57-59%, and SOEC shows the highest efficiency at approximately 89%. Power conversion units must exhibit a high power conversion ratio and a low output current ripple to implement a successful electrolysis process. If power converters do not inherently show such characteristics, they must be adjusted.

Multiple DC-DC power converters are used in a DC bus to support the green hydrogen production for weeks. Multi-level converters driven by control algorithms can be a great option to improve system efficiency. A recent study focused on implementing and comparing different DC power converter topologies in green hydrogen production. Examples include DAB (dual active bridge) and buck converters - standard, synchronous, stacked, quadratic, and superimposed types.

Control algorithms are difficult to implement in DAB converters due to the increased number of power modules. Standard buck converters produce high ripple and switching losses. With the help of external electronic filters, such as LC filters and freewheeling diodes, a standard buck becomes a cheaper option for commercial usage. Quadratic buck converters show one of the highest efficiencies, about 82%, but costs increase due to power MOSFET switches.

:quality(80)/p7i.vogel.de/wcms/16/62/16623172b80c3c9a81a9643d7ca16d61/0126331664v2.jpeg)

ENERGY STORAGE

Scalable supercapacitor technology made from graphene

Future

Electrolyzer plants, incorporating power electronic devices, are either in pilot mode or fully operational in many parts of Europe and North America. Electricity and power components contribute to more than 60% of the operational costs of such plants. As mentioned above, heat is dissipated several times in the loop, which can increase costs if not managed.

Bidirectional hydrogen in such loops prevents electricity wastage during overproduction. H2 loops can store excess renewable energy for prolonged times to later produce power for industrial and commercial spaces. Applications include grid services, heavy-duty cycle systems, load balancing, and seasonal balancing during low solar visibility or wind periods. Furthermore, hydrogen-based electricity can support bipolar grids in residential projects.

The average efficiency of an electrolysis process using efficient power units is about 70%-85%, which is acceptable. However, fuel cells have their own losses. The average efficiency of the long-term process loop ranges between 50% and 80%. As a result, hybrid energy systems with wind and solar power can offer better performance.

(ID:50662331)

:quality(80)/p7i.vogel.de/wcms/7d/b4/7db4fc5b8cd18e6eb2c864a3c329f177/0129545524v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f5/d2/f5d2bce7c01775fe62d4c6ecebc8c5ba/0129188745v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/38/cb38bf951c0af8a8de423fedce2489d8/0129352475v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b8/13/b8139abf82c98aa04248a4a119d28c13/0129194616v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/e6/eae6aee30071e67a5627027974437134/0129544613v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/40/6040b2e00aef20b4f9d92e8ac9f79c32/0129349725v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/99/3e997b758543c9a581667cee711b6938/0129540100v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6e/fd/6efdf487345688ca2b71ae23a398bc5f/0128553399v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/f0/ccf0b07809eaa14635374ad332fd7ea3/0129431466v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8a/d5/8ad5fce4f456b8cd4507598c6c3d92c8/0129546435v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/62/95/6295c25c8dc1a/schunk-sonosystems-300dpi.png)

:quality(80)/p7i.vogel.de/wcms/af/f2/aff2fcbebdde7822fc2ec9a43f06eccc/0125713659v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/a5/dea59989dd528b35b1803445d600ef88/0124760917v2.jpeg)