BUILDING A GREEN FUTURE Transparency, targets, and teamwork: The keys to sustainability progress

Sponsored by

Sustainability is a team effort – but how do you take the first step? From developing customized assessment methods to integrating them into financial reporting: Discover how Henkel tackles the challenge and makes sustainable progress measurable.

Sustainability, by definition, is the preservation of resources through multiple avenues. These include, for example, emission reduction to protect the climate, reuse and recycling to prolong or repurpose a product’s life, and efficient use of energy and production inputs to reduce cost and environmental impact. To drive meaningful sustainability results and create value, it is critical for an organization first to identify sustainability objectives. Starting with the end goal in mind allows analysis of R&D, procurement, and production practices to ensure alignment with specific processes or to challenge existing paradigms to achieve desired objectives.

Sustainability is a team effort, and to be impactful, transparency is imperative. Sharing where we have made progress – and where we have tried but not yet succeeded – is vital to fostering transparency and trust between different companies. It takes trial and error, a lot of analysis, and partners with a can-do attitude. No one organization can do this on their own.

Developing a comprehensive strategy and moving to implementation with specific, measurable milestones is easier said than done; this demands significant cross-functional collaboration and agreement on what can be reasonably accomplished. In addition, it requires transparency on the status quo in connection with a very complex topic that is not yet part of the mainstream reporting systems of most companies. While organizations may differ on methodology, establishing these processes is essential to driving measurable, successful outcomes. In Henkel’s case, the company began by developing a customized approach to assess the sustainability impact of its product portfolio and implementing the metrics into financial reporting, target setting, and portfolio steering. Henkel also engaged a third party to audit the assessment methodology, enabling the company to credibly share information about the sustainability impact of the product portfolio with customers and external partners. Though the complexity can seem daunting, beginning with a transparent assessment is essential to understand the starting point for setting targets to achieve a more holistic sustainability program.

Alignment and coordination is critical

A commonly cited statistic is that 80 % of a product’s environmental impact is influenced during the design phase. Maija Kirveennummi, Sustainability Lead for the Industrial business unit of Henkel Adhesive Technologies, agrees with this, and notes that implementing certain key performance indicators (KPIs) in design guidelines for a clear understanding of sustainability materiality topics and prioritization to assess tradeoffs is difficult – but vital. “Individual designers can influence the product carbon footprint and circularity by considering factors like raw materials emission intensity, product lifetime, and repairability,” she says. “And the desired outcomes should be driven by central guidance between different functions to ensure that objectives are aligned, for example, between R&D and purchasing. Today, that only happens in isolated cases. Though there may be tangible and measurable metrics for the result, considerations of specific milestones throughout the process and buy-in from all partners are musts.”

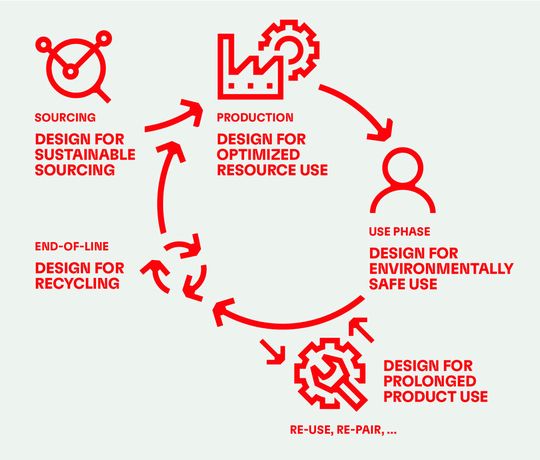

For example, when evaluating a product design, many touch points contribute to its overall environmental impact. It may be built using less energy, with renewable raw materials, with features that will extend its lifetime, or all of the above. What are the costs associated with these factors? Are all objectives realistic, given certain quality requirements or regulatory standards? These questions, among others, must be asked and answered. Analyzing the sustainability impact of a product along its entire lifecycle (as shown in the example Figure 1 below) during the design phase is a new way of thinking for many companies.

Clear targets drive the direction

With sustainability as a core corporate value, Henkel ensures specific outcomes by setting intentional objectives at a high level. All new product developments within Henkel Adhesive Technologies are evaluated based on their sustainability contribution (Figure 2). When a product development project is initiated, a holistic sustainability assessment is conducted. Later, an analysis of the product’s carbon footprint along its value chain is calculated. These are essential evaluation elements required to understand the sustainability impact.

This is demonstrated throughout the company’s product portfolio, like Henkel’s ongoing development of solutions that enable design for disassembly, its successful launch of products that integrate renewable raw materials, and its contributions to solar energy efficiency with a novel materials portfolio. Sustainability metrics are also a core element of Henkel’s manufacturing footprint; the company now has 14 carbon-neutral plants and several, including its aerospace facility in Montornès del Vallès, Spain, that operate entirely with renewable electricity.

This approach doesn’t impact Henkel alone; it has upstream and downstream influence. As a partner supplier, Henkel’s efforts impact customers’ scope 3 targets, as do the initiatives of Henkel’s suppliers on its overall footprint. This type of engagement with partners across the value chain delivers further sustainability progress. One example of this collaboration is Henkel’s work with partner Schneider Electric, where each company has benefitted from the other’s expertise, products, and commitment to Net Zero.

Leveraging experiences, trials and errors, and successes, Henkel is helping customers integrate sustainable practices at all levels of product development or even for post-production repair. Every customer’s products, applications, and levers are different, and that is where Henkel’s technical depth and sustainability know-how can create additional value. In one case, Henkel developed a new chemistry that allowed combining cleaning and coating steps for a white goods manufacturer, resulting in 30 % less water consumption, 6 % less energy use, and saving 100 metric tons of CO2 annually. This example is one of many where open lines of communication, innovation, and a sustainability mindset have delivered meaningful, cost-effective results.

An invitation: Let’s create sustainable value, together

Henkel is actively engaged in the sustainability journey, codeveloping solutions, implementing actions, measuring progress, and reporting the results. Working with our suppliers, partners, and customers is the only way to make the green transition happen.

“There is no off-the-shelf solution that can be replicated from customer to customer,” explains Maija, emphasizing that KPIs differ depending on various factors such as product use and lifetime, components used, and the application. “We take a holistic view, drawing on experiences with others in the value chain and our product portfolio to develop an approach that delivers sustainable value for our customers. These deep partnerships, underpinned by transparency, result in quantifiable benefits to all parties.”

When it comes to sustainability, companies can choose to create solutions or live with the status quo. But the status quo is bad for the earth, not productive for humanity, and doesn’t foster vibrant, innovative businesses. If you are ready to engage and create a sustainable future, Henkel is ready to make it happen.

We don’t claim to have all the answers. But we are committed to finding them alongside our partners to achieve purposeful growth together.

Listen to the podcast: https://next.henkel-adhesives.com/us/en/podcasts/sustainability-takes-partnership.html

Learn more: https://next.henkel-adhesives.com/us/en/about-us/sustainability.html

(ID:50278479)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c0/3a/c03a16bc6a7a3446e3ec1eb0016d5aec/0124285381v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1a/42/1a421f72a7f7a060e91c4e11d60a275b/0123085333v4.jpeg)