BASIC KNOWLEDGE: TRANSFORMERS Three-phase transformers explained

Related Vendors

The big green boxes you see on the roadside are three-phase transformers. Just like a single-phase transformer, a three-phase transformer “transfers” voltage from one circuit to another. However, a three-phase transformer deals with three phases instead of single-phase. The article explains the three-phase transformer through its working, needs, applications, advantages, and disadvantages.

Three-phase transformers are typically used for electricity distribution in commercial spaces. The market of three-phase distribution transformers was valued at USD12.9 billion in 2023. It is estimated to grow from 2024 to 2032 at a CAGR of 9.4 %. Three-phase transformers are electronic devices that use three-phase AC current to transfer electrical energy between circuits in a three-phase power system.

Just like single-phase transformers, the three-phase transformer operation is based on Faraday’s laws of electromagnetic induction. These devices either step up or step down the voltage while maintaining the same level of frequency between primary and secondary windings. As a result, three-phase transformers generate a stable level of output power.

Why do we need three-phase transformers

Three-phase transformers are used to transfer electricity over long distances to power distribution systems, large-scale electrical networks, and commercial and industrial spaces. This is because commercial areas need large amounts of HVAC electricity for equipment and lighting every day. Three-phase transformers do not transfer electricity to residential areas due to low power requirements.

Applications of three-phase transformers

Power transmission and distribution

Three-phase transformers are used to transmit high-voltage over long-distance transmission lines. In substations, the high voltage is stepped down to a lower value for real-time supply.

Industrial applications

Three-phase transformers offer effective power conversion and delivery to power electronic equipment and industrial machinery.

Commercial buildings

As mentioned above, commercial spaces require large amounts of power to run HVAC systems (Heat Ventilation Air Conditioning), excessive lighting, equipment, elevators, refrigerators, etc. Three-phase transformers provide a stable and balanced power supply to HVAC equipment and systems for continuous operation.

RES (Renewable Energy Systems)

Renewable energy systems and EVs require high power for processing. Three-phase transformers effectively integrate with the grid for efficient voltage conversion.

:quality(80)/p7i.vogel.de/wcms/6f/7a/6f7a0fc82b4fcbe38c8a4a95cd5ddb37/88318617.jpeg)

Electrical Power

Basics of an electrical power transmission system

Three-phase transformer construction

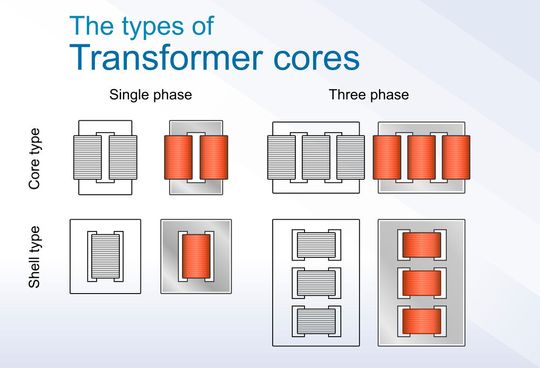

Depending on cores, three-phase transformers can be constructed in two ways. Shell-type and core-type are two constructions.

Three-phase transformer bank (Shell-type transformer)

The first method is to connect three single-phase transformers to form a three-phase transformer bank. The core features five limbs, on which transformer coils are wrapped. Such a construction occupies large amounts of space. It was used in earlier times.

Core-type three-phase transformer

The second method is to wound three-phase windings on a single core. To prevent the loss of magnetic fields, transformers use a core made from silicon steel or ferromagnetic material. The single core has three limbs in the same plane, on which windings are placed. This construction method offers a compact design to save costs and space. Fewer units of core material and copper are used.

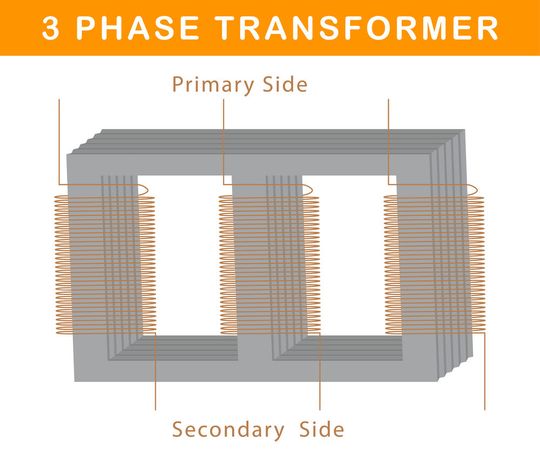

High Voltage (HV) Side

The primary windings are connected to a low-voltage or high-voltage power source. This side is capable of handling high voltages. There are a total of three primary coils in three-phase transformers.

Low Voltage (LV) Side

The secondary windings are connected to a lower-output voltage. There are a total of three secondary coils in three-phase transformers. The low-voltage coils are placed closest to the core. Separated through insulation, the high-voltage coils are wrapped over low-voltage coils.

Three-phase transformers use insulation systems like oil, paper, tape, pressboard, and laminated wood. A tank protects and houses the oil. Cooling systems manage an excessive amount of generated heat. In addition, three-phase transformers may use tap changers, gas-actuated relays, thermometers, breathers, and pressure relief systems to ensure safety.

How do three-phase transformers work?

The source is connected to the primary HV windings. The input of three-phase power energizes all these primary HV coils. An AC current flows through the primary HV coils to generate a time-varying magnetic field around them. As a result, a changing magnetic flux is established at the transformer iron core.

The three coils generate an alternating magnetic flux that combines to create a magnetic field in the transformer's iron core. It links the HV and LV sides at the transformer iron core. As per Faraday’s law of electromagnetic induction, the changing magnetic flux induces an EMF in the secondary LV coil.

The induced emf is a voltage, whose magnitude depends on the rate of change of magnetic flux. As the circuit of the secondary LV windings is complete, an AC current flows in secondary coils. The frequency at the input side remains the same at the output side of three-phase transformers.

Three-phase transformer types

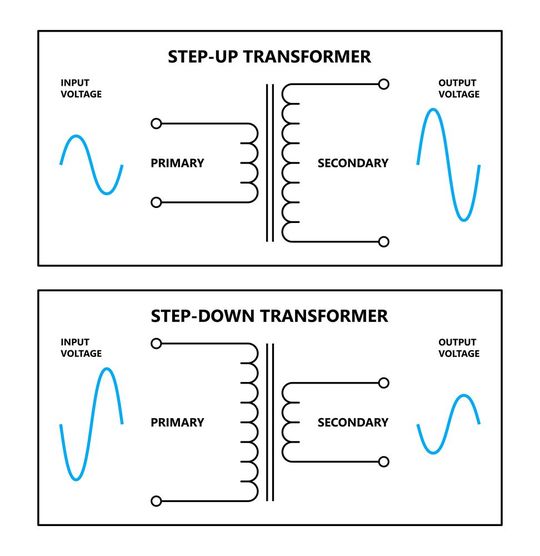

Similar to single-phase transformers, three-phase transformers are categorized into step-up and step-down transformers.

Three-phase step-up transformers

Three-phase step-up transformers take a low-voltage input to generate a high output voltage. In simple words, these devices “step up” or increase the input voltage at the output. Three-phase step-up transformers are used in transmission lines to transfer high-voltage over long distances.

The number of primary winding turns is higher than the number of secondary winding turns. The primary coil is connected to a high-voltage source. The AC current flowing in the primary winding generates a time-varying magnetic field, resulting in establishing a changing magnetic field at the transformer iron core.

As per Faraday’s law of electromagnetic induction, the changing magnetic flux induces an EMF in the secondary coil. As the number of turns in secondary windings is lesser than the number of turns in the primary windings, the flux generates a small voltage at the output.

Three-phase step-down transformers

Three-phase step-down transformers take a high-voltage input to generate a lower output voltage. In simple words, these devices “step down” or decrease the input voltage at the output. Three-phase step-down transformers are used to transfer safe voltage levels to commercial places.

The number of primary winding turns is higher than the number of secondary winding turns. The primary coil is connected to a high-voltage source. The AC current flowing in the primary winding generates a time-varying magnetic field, resulting in establishing a changing magnetic field at the transformer iron core.

As per Faraday’s law of electromagnetic induction, the changing magnetic flux induces an EMF in the secondary coil. As the number of turns in secondary windings is lesser than the number of turns in the primary windings, the flux generates a small voltage at the output.

:quality(80)/p7i.vogel.de/wcms/d5/16/d516de80794e43096132c1b4b90907b0/0112972182.jpeg)

POWER TRANSFORMERS

Step up vs. Step down transformer – what’s the difference?

Three-phase transformer winding arrangement

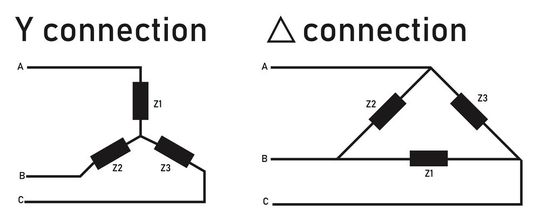

In three-phase power systems, there are two winding arrangements named Star or Wye and Delta. These winding arrangements are based on the placement of primary and secondary windings. This is somewhat similar to series and parallel connections done with resistors.

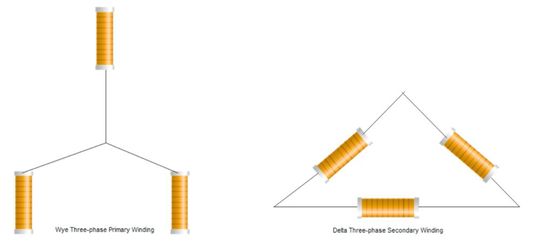

Wye (Star)

In a Star or Wye configuration, one end of each coil is connected and the other end of each coil is connected to the phases. The Wye configuration represents the letter “Y”. The neutral wire and ground are connected to the central point of the three coils. It is done to connect three-phase motors. The Wye connection is a four-wire system.

Delta

In a Delta configuration, all transformer coils are connected end-to-end. The phases are connected between the coils. The Delta configuration represents a triangle. Delta configuration is of two types: high leg Delta and open Delta. The Delta connection is a three-wire system.

Three-phase transformer winding configurations

Based on Delta and Wye configurations, there are four types of three-phase transformers. The packaging of three-phase transformers mentions the type of coil arrangement.

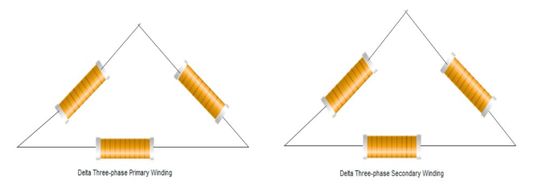

Delta-Delta

Three-phase Delta-Delta Transformers are used to handle low-voltage and large amounts of current. In this configuration, line-to-line voltages are equal to phase voltages. There is no phase shift under unbalanced loads. Delta-Delta configuration traps harmonic components, leading to transformer efficiency.

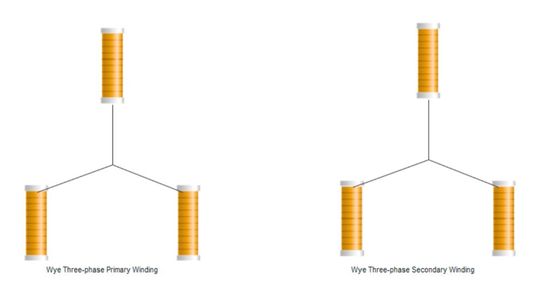

Wye-Wye

The primary and secondary windings are connected in a Wye configuration. This connection is a four-wire system from the input and output sides. The line voltages are root three times the phase voltages. Three-phase Wye-Wye Transformers are used to handle high-voltage and small-current. Voltage imbalance occurs under imbalanced loads. In addition, the Wye-Wye configuration is prone to harmonic distortion.

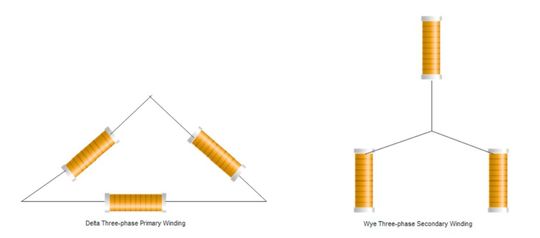

Delta-Wye

The primary windings are connected in a Delta while the secondary windings are connected in a Wye configuration. The primary windings are connected in a Delta while the secondary windings are connected in a Wye configuration. Three-phase Delta-Wye Transformers are used as step-up transformers. The primary Delta connection offers immunity from third harmonic voltage.

Wye-Delta

The primary windings are connected in Wye while the secondary windings are connected in a Delta configuration. Three-phase Wye-Delta Transformers are used as step-down transformers. Delta winding suppresses the third harmonic voltage but an undesirable phase-shift occurs in the circuit.

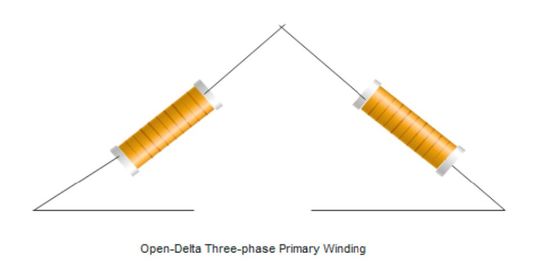

Open-Delta

Open Delta leg connection center-taps one leg of the Delta-connected secondary side. It uses two single-phase transformers in a Delta connection to supply three-phase power to the load. The absence or removal of one coil drops efficiency up to 57.7 % of the Delta-Delta connection.

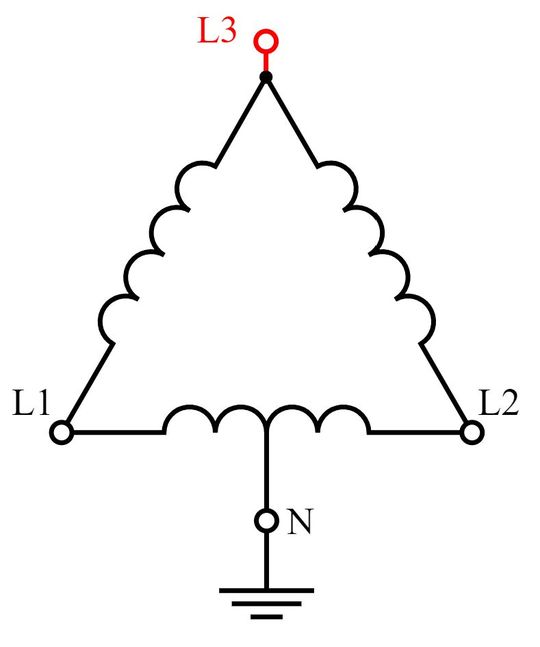

High-leg Delta

In a high-leg Delta connection, the three-phase transformer can produce both three-phase and single-phase power outputs.

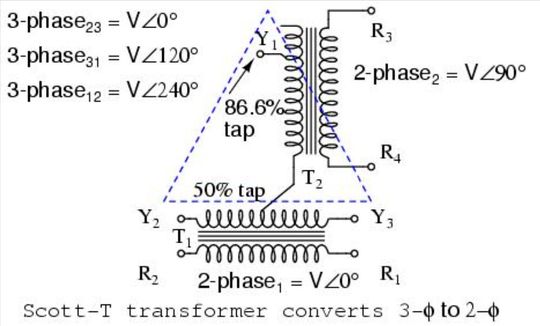

Scott-T Transformer

The Scott-T transformer connection enables producing two-phase electric power from a three-phase source.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/60/a6/60a6321aee790/seddik-bacha.jpeg)

KEYNOTE PCIM EUROPE 2021

HVDC grid challenges locks and opportunities

Advantages of three-phase transformers

Three-phase transformers are highly efficient and reliable for commercial spaces. In most applications, three-phase transformers are considered to be a better choice compared to single-phase transformers.

High power handling capacity

Three-phase transformers are capable of handling thousands and tens of thousands of volts without any dangerous consequences. These devices tend to have a lower stray magnetic field and significantly lower operating temperature due to the addition of coolant.

Stable output

Three-phase transformers provide stable power to loads in commercial settings. The quality of regulated power delivered by three-phase transformers has minimal harmonic distortion, voltage fluctuations, and phase imbalances.

Disadvantages of three-phase transformers

Complex design, heavy size, extreme caution, overheating, noise, and single-failure risk are some disadvantages of three-phase transformers.

Eddy current

The magnetic field moves through the core to induce an eddy current. A large amount of eddy current results in generating excess heat. It is an undesirable effect of Faraday’s laws of electromagnetic induction. As a result, cores made from thin laminated sheets effectively reduce eddy currents.

High costs

Three-phase transformers are heavier and bulkier compared to single-phase transformers. If one of the phases is overloaded or needs repair, the entire unit is taken offline for repair. The cost of installation, maintenance, and repair is high.

References

(ID:50198080)

:quality(80)/p7i.vogel.de/wcms/b8/13/b8139abf82c98aa04248a4a119d28c13/0129194616v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/80/6280da00d591873bf8f0b2a70e5986e0/0129064771v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/f6/60f60a22a65f51b4f3603fd1bf64401a/0129067839v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/97/bc97cce107109a551f26fb8076ae1da8/0129190430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/40/7d406bd959b3a9127c33a66157f9030a/0128339184v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/65/22/65223bc58811ced76adbfa7b5615d532/0129061536v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/20/ea20c0beb93f34ab43b28750644bbdca/0128983445v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/0a/b10a283cdf3e5f156781a7273c71a7e0/0129107484v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/67/e2/67e2a1ef13aba/logo-ab-rgb-1.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:fill(fff,0)/p7i.vogel.de/companies/69/30/693022b11e5db/logo.jpeg)

:quality(80)/p7i.vogel.de/wcms/0d/d0/0dd02f3d5a1c83c1be444f73910e6b30/0126472071v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7a/a5/7aa50649486f059b1d7111f508c5c6e7/0128629162v2.jpeg)