MEASUREMENT SOFTWARE The basics of order analysis with OXYGEN

Sponsored by

In the world of rotating machines, vibrations tell a silent but powerful story - especially when studied via order analysis. Order analysis gives engineers a variety of insights into the examined system based on vibration and rotation measurements.

What is order analysis?

In the context of rotor dynamics, order analysis refers to studying the noise or vibration in rotating machinery or vibrating components. It is based on vibration and speed measurements with at least one acceleration sensor as well as information about the speed and angular position of the rotor, which is determined using encoders or tachometers. In contrast to frequency analysis, order analysis plots the energy content of the vibrations against the order, which represents the harmonic components that correspond to a multiple of the rotor’s basic speed.

Why is it so important?

In essence, order analysis offers a comprehensive understanding of an entire rotating system. It is a powerful tool, especially for machine diagnostics, and helps to

- detect misalignment and bearing faults,

- determine unbalance in the machinery,

- detect resonances,

- and more

Overall, it allows for easier interpretation of vibrations and makes it possible to diagnose potential problems, optimize performance and ultimately ensure the reliability and efficiency of rotating machinery.

How does order analysis work?

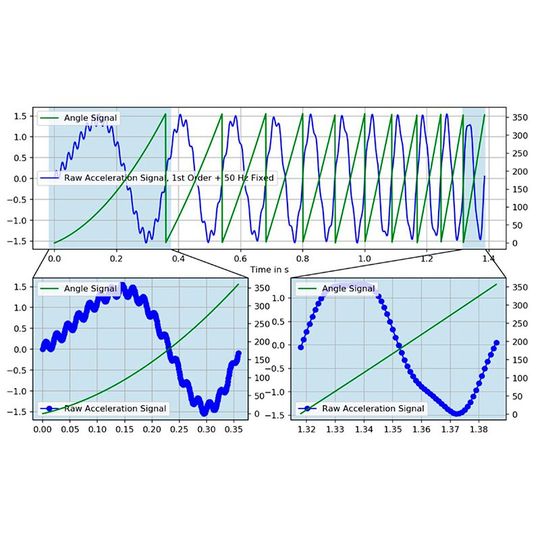

First of all, it is necessary to collect vibration data from the DUT (e.g. engine), for instance with an accelerometer. Secondly, you eliminate the noise from the raw vibration signal to retain only the relevant frequency range. In addition, it is required to obtain the rotational speed of the rotor (e.g. using a tachometer) and synchronize the vibration data with blocks of one rotor revolution. This allows to identify orders corresponding to the harmonic components of the rotating machine. The next step is to track frequency variations.

To do so, separate the vibration signal into blocks (Fig. 1), with each block representing one revolution, apply additional filtering and resampling operations to enhance accuracy and transform each individual block into the frequency domain via Fourier transform. Finally, you visualize the result as a 2D-color diagram.

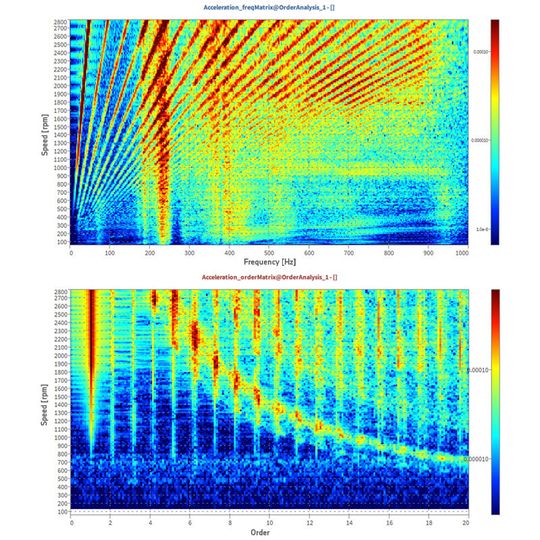

Fig. 2 shows the resulting diagrams obtained with DEWETRON's measurement software OXYGEN. The top panel shows the analysis in the form of a frequency matrix (frequency spectrum vs. rpm), while the bottom panel shows it in the form of the conventional order matrix (order spectrum vs. rpm).

Data interpretation

Clear line patterns can be recognized in both matrices. In the order matrix, vertical lines and curved structures are observed. Vertical lines denote the energy content of the rotating components, remaining constant across the entire rpm range due to each order representing a multiple of the fundamental rotation. Conversely, the curved lines in the order matrix signify the energy content of the structural components, which can vary at different speeds. In the frequency matrix, the pattern is reversed: non-vertical linear lines describe the energy content of the rotating components across multiple frequencies, while vertical lines indicate structural components. The presence of these vertical lines in the frequency matrix is attributed to the dominance of resonance frequencies in the vibration spectrum of structural components, reflecting the influence of normal modes.

Whether in automotive, aerospace, manufacturing or other industries, order analysis with OXYGEN is an always powerful tool. It offers a user-friendly yet highly effective implementation to quickly and comprehensively analyze your system.

(ID:49861906)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/4b/604b5c9692acc/unnamed.png)

:quality(80)/p7i.vogel.de/wcms/f0/e0/f0e0561de9eba27f7b1eced122929504/0123679425v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/37/64/376449c482d7bc5493c77d057638fe59/0126287882v2.jpeg)