ARTICLE SERIES PART 4 Smart battery backup for uninterrupted energy: BBU shelf operation

Related Vendors

This article details Analog Devices' hardware and software for the Open Compute Project (OCP) Open Rack V3 (ORV3) Battery Backup Unit (BBU) Shelf. Its primary duty is to create communication between its BBU module and present readable data and information to the user via a graphical user interface that is carefully crafted for this type of application.

Article series overview

Delve into our in-depth article series that explores the intricacies of designing innovative and reliable battery backup systems for modern data centers, ensuring seamless operations and energy efficiency even during power disruptions.

Part 1: Electrical and Mechanical Design

The first part of the series addresses the key electrical and mechanical design considerations for the Open Rack Version 3 Battery Backup Unit, highlighting solutions that enhance efficiency and system reliability during power outages. Click here for Part 1

Part 2: BBU Microcontroller Functions and Operations

The second installment focuses on the microcontroller's role within the BBU, detailing how its functions and operations ensure high efficiency and reliability, while emphasizing the importance of smooth hardware and software integration. Click here for Part 2

Part 3: Battery Management System

Part three provides insight into the vital role of the Battery Management System, explaining how it monitors and optimizes the performance and lifespan of batteries through effective management of state of charge, state of health, and cell balancing. Click here for Part 3

The backup battery shelf is an important feature of power management systems in an OCP ORV3 architecture and data center application, especially in the field of uninterruptible power supply (UPS). These shelves, with a precise design focused on housing and organizing backup batteries, emerge as key sentinels, assuring the smooth operation of critical equipment in the midst of power outages and voltage variations.

The critical importance of dependable power backup systems is unmistakable in our modern era, which is distinguished by technical sophistication. The stability of data centers, telecommunication hubs, and server rooms is essential to the operation of companies, putting the onus on a strong power backup system. In this case, backup battery shelves play a key role by serving as the foundation of these systems. These shelves, which act as the basis hub for the efficient storage of battery backup units, create a link that increases the readiness of critical power reserves. Their primary goal is to accommodate and manage up to six BBU modules, each precisely aligned to house lithium-ion batteries paired with power converters. The architecture of these shelves has been meticulously adjusted, effortlessly merging space use efficiency with accessibility, allowing for streamlined maintenance and simple replacement operations.

One of the key benefits of these battery backup shelves is the centralization and organization of BBU modules inventory. The availability of a defined storage system allows for easy tracking, labeling, and maintenance of BBU modules, reducing the danger of misplacement or confusion, especially in crucial situations. Furthermore, this centralized hub has shown to be a true benefit for battery health monitoring. This structure makes regular inspections, tests, and replacements easier.

:quality(80)/p7i.vogel.de/wcms/3d/de/3ddebf253c7959c9d1f9601930be3eda/0118506387v2.jpeg)

ARTICLE SERIES PART 1

Smart battery backup for uninterrupted energy: Electrical and mechanical design

The varied assortment of sizes and configurations in which BBU shelves echo versatility, adeptly fitted to the individual requirements of varying industries and institutions. The modular design of certain shelves provides flexibility, allowing for future development in power demands. Meanwhile, these versions of shelves contain integrated monitoring systems that provide real-time battery status information. Details such as voltage levels, temperature, module activities, and remaining capacity are displayed at a glance, allowing for preventative maintenance and ensuring that batteries are always ready to provide power at the most critical of times.

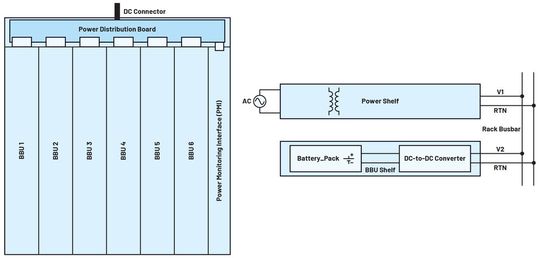

BBU shelf overview

As defined by the OCP for their new architecture for ORV3, the Open Rack Power architecture consists of a centralized scalable power shelf and a BBU shelf that distributes power over a common bus bar to payload devices (IT Gear). This spec will define the BBU shelves that fit into the Open Rack. The BBU shelf will contain six BBU Modules with 5+1 redundancy to provide DC power to all payloads within the rack. When an AC power outage occurs, the BBU shelf can provide backup power up to the maximum rating of the power shelf for a specified backup time period. BBU shelf backup time allows the rack to be moved between power sources without interrupting IT gears and allows draining or moving applications before power is lost.

Shelf microcontroller firmware

The

used in the BBU application is the MAX32625, an ultra-low-power ARM Cortex-M4 microcontroller. The shelf microcontroller is responsible for multiple processes.

- Communicating to the host computer via MODBUS protocol

- Communicating to the modules via MODBUS protocol

- Handling periodic charging of modules

- System control modes

Communicating to the host computer via MODBUS protocol

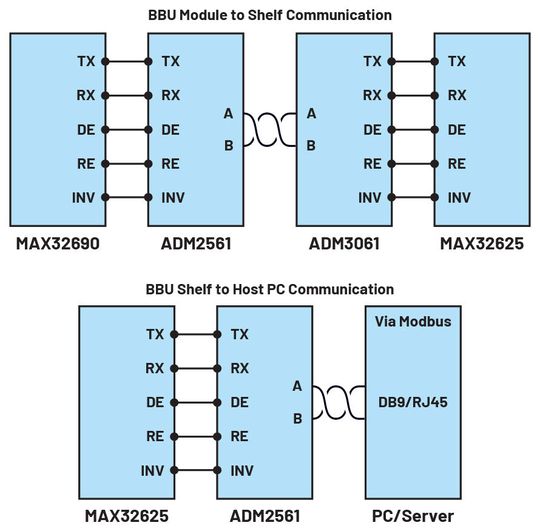

In Figure 2, the shelf microcontroller performs a critical role in establishing seamless communication with the host computer over the sturdy RS485 interface by acting as an expert MODBUS server. Its primary function is to collect data from numerous modules in real-time, which it does tirelessly. This accumulated data is then delivered to the host computer, where it is used to populate a dynamic graphical user interface application, providing a visually enhanced depiction. When communications are received from the host computer, the shelf microcontroller acts as a gatekeeper, methodically authenticating the validity and integrity of each message. When the microcontroller is satisfied with the message's authenticity, it quickly formulates its answer, drawing on the amount of information stored in the holding registers. This carefully crafted response contains the answers needed by the host computer, presented in a structured fashion.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/63/be/63beb9273d536/web-vorschaubild-webkon-pb-2023-02-14.png)

WEB CONFERENCE: BMS & uninterruptible power supply

Communication in BMS & point-of-load uninterruptible power supply

However, the shelf microcontroller does not fail when the incoming message is polluted by anomalies, casting doubt on its validity. It quickly assumes the role of an effective communicator, responding with an error message based on the MODBUS protocol. This error notice alerts the host computer to the abnormality, allowing appropriate corrective actions to be taken.

In essence, the shelf microcontroller's importance is reflected in its multifaceted role as a data conduit, a data integrity guardian, and a responsive informant, all of this contributes to the orchestration of a robust and dependable communication framework within the realm of MODBUS-powered interactions.

Communicating to the modules via MODBUS protocol

In Figure 2, the shelf microcontroller's key role becomes clear as it seamlessly shifts between the roles of a MODBUS client and a MODBUS server, coordinating a complex and efficient communication ecosystem. When interacting with the many BBU modules, the shelf microcontroller plays the role of a MODBUS client, initiating and maintaining talks with each unique module. These BBU modules stand as servers in their own right as data conduits, continuously updating their holding registers with the most up-to-date information. The shelf microcontroller embarks on a cyclical journey while operating in synchrony. It traverses the BBU module environment, capturing telemetry data from each module in a cyclic cadence. This data which provides useful insights, is carefully stored within the microcontroller's memory, poised and ready to answer should a question from the host computer arise.

However, the shelf microcontroller's purpose is not limited to client-server interactions within the BBU system. It transforms into a MODBUS server, delivering the collected data to the host computer upon request, creating a crucial bridge between the host computer and the numerous BBU modules. At the same time, it continues its function as a MODBUS client, organizing interactions with the BBU modules and ensuring that the information is up-to-date and accurate.

In essence, the shelf microcontroller embodies versatility and adaptability, adeptly dressing as both client and server, encouraging an interplay between the host computer and the BBU modules. This interconnection demonstrates its ability to maintain a solid communication structure, increasing the overall system's efficiency and dependability.

Handling periodic charging of module

According to the Open Compute Project requirements, a BBU module must be charged on a regular basis because the battery pack leaks current while on standby. Because a BBU module can only be charged periodically once every 10 days, the shelf microcontroller must monitor and manage which BBU modules will be charged. As a result, periodic charging is initiated by the shelf microcontroller, which uses a unique MODBUS protocol command to determine which BBU modules require periodic charge. A basic necessity for the BBU modules within the system's architecture derives from the Open Compute Project's precisely developed standards. These modules, which are key components of the setup, must be charged on a regular basis. This requirement stems from the phenomenon of current leakage that the battery pack undergoes during standby periods. As a result, periodic charging becomes not just a desire but an obligatory duty in order to retain optimal performance and operational reliability.

:quality(80)/p7i.vogel.de/wcms/44/ac/44ac5c485286a6b5fbc445a46e8b26e0/0119263672v2.jpeg)

ARTICLE SERIES PART 2

Smart battery backup for uninterrupted energy: BBU microcontroller functions and operations

System control modes

Finally, the Open Compute Project suggests adding a user control to override the BBU module operations. Through a MODBUS, the user can adjust the operation of a single BBU to determine whether it requires charging or discharging.

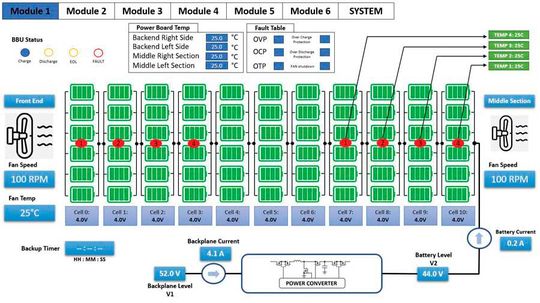

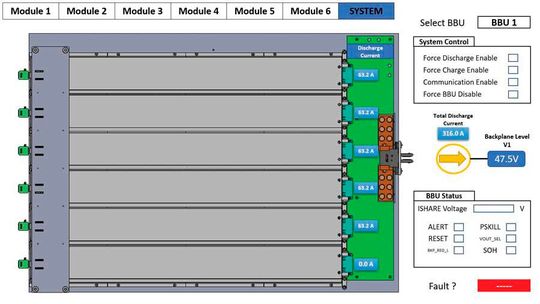

BBU shelf graphical user interface

The BBU module graphical user interface (GUI) is divided into several sections that provide important information to the user. These components and functions are detailed below: See Figure 3.

- Module operation status indicator

- Module internal temperature readings

- Module fault indicator table

- Fan speed indicator (in rpm)

- Power Converter metrics information

- Cells information (voltage and temperature)

Module operation status indicator

On the GUI, there are at least 4 LED indicators:

- The blue LED signals that the BBU module is in charge mode operation.

- The first amber LED indicates that the BBU module is in discharge mode and providing backup power to the backplane of the data center.

- The second amber LED indicates that the BBU module needs to be replaced and is in its end-of-life (EOL).

- The red LED provides information to the user that the BBU module is experiencing a fault.

Module internal temperature readings

Aside from the BBU operation status, the internal temperature of the module is also displayed in the GUI. At least nine temperature sensors are carefully placed within the battery stack and power board. The LTC2991 provides digital temperature readings to the main MCU, while the ADBMS6948 provides analog battery stack temperature readings.

Module fault indicator table

The GUI has a fault table that indicates different types of faults being triggered during the module operations. The module faults are the following:

- OVP – Over Voltage Protection

- OCP – Over Current Protection

- OTP – Over Temperature Protection

- Charge and Discharge Over Protection

- FAN shutdown

Power converter metrics

While the module is running, the GUI is a significant resource, providing vital metrics for both the battery stack and the backplane. These metrics have a broad scope, encompassing crucial data such as input and output voltages as well as currents. This dynamic interaction between module operation and GUI provides users with a complete and real-time awareness of the system's performance and energy dynamics.

Cell information

The GUI displays the battery stack cell voltage and temperature level. This data is critical for determining the battery stack's state of health (SoH) and state of charge (SoC).

Within the BBU module GUI, a window comprising both a brief summary and user control functionalities is present. This particular tab furnishes the capacity to monitor all six BBU modules while affording individual control over a specific BBU unit, including the capability to enforce operational decisions. Please refer to Figure 4 for a visual representation.

- Address Selector

- Shelf System Control

- Shelf System Parameters

- Shelf Fault and Current Sharing

:quality(80)/p7i.vogel.de/wcms/84/be/84be6d90d277bbc376802b5da267aba1/0119256325v2.jpeg)

ARTICLE SERIES PART 3

Smart battery backup for uninterrupted energy: battery management system

Address selector

Users can smoothly access the specified BBU modules by strategically selecting the precise BBU slot address. This strategic allocation is not random; it is a precautionary step aimed at preventing MOBUS communication clashes, which is accomplished by predefining a set BBU shelf slot address.

Shelf system control

Empowering users with the authority to modify BBU operations, they can prompt it to either charge or discharge over its operational span. Opting for the force discharge mode results in an elevation of the boost voltage from 48V to 51V, facilitating backplane power while maintaining the undisturbed operation of the Power Supply Unit (PSU) within the data center. This nuanced control ensures an optimized balance between BBU functionality and the seamless running of the larger infrastructure.

Shelf fault and current sharing

The summary table displays any faults detected on the six BBU modules and notifies the user. It is the quickest technique to locate any flaws in the BBU shelf. Furthermore, during BBU module parallel or redundancy operation, the current share bus indicator shows a bus voltage of 7V when the backplane load is at its maximum and 10.5V when peak load operation is in effect.

Summary

The BBU Shelf serves as a crucial component in a reliable power management system. These shelves securely interconnect to create a stable environment for a battery backup system, acting as a central hub for efficient administration. This results in a seamless operation where critical systems remain uninterrupted and safeguarded against power outages and voltage fluctuations. The well-designed BBU Shelf is an indispensable guardian within data centers, telecommunications networks, or any environment where an uninterrupted power supply is essential. Its primary mission is to ensure the continuity of operations, enhance dependability, and maintain a robust power infrastructure.

A subsequent article in this series will explain how to select components for the BBU auxiliary circuit. This will be used as a criterion and benefit when selecting parts for powering critical devices and reducing design irregularity.

Reference

David Sun, “Open Compute Project Open Rack V3 BBU Shelf Rev 1.1”, OCP Rack/Specs and Designs, Sept 2022.

* Christian Cruz is a staff applications development engineer at ADI Philippines. He holds a bachelor’s degree in electronics engineering from the University of the East in Manila, Philippines. He has more than 12 years of engineering experience in the fields of analog and digital design, firmware design, and power electronics, which includes power management IC development as well as AC-to-DC and DC-to-DC power conversion. He joined ADI in 2020 and is currently supporting power management requirements for consumer and cloud-based infrastructure business units and system communications applications. He can be reached at christian.cruz@analog.com.

* Marvin Neil Solis Cabueñas graduated with a bachelor’s degree in electronics engineering from De La Salle University in Manila, Philippines. Before joining ADI in 2021, Marvin worked as a systems engineer for Azeus Systems Philippines, Inc., then worked as a network engineer for Technistock, Philippines, Inc. from 2014 to 2017 and as a research and development engineer for Nokia Technology Center Philippines from 2017 to 2020. He has more than nine years of work experience in different fields such as embedded systems programming, digital signal processing, simulation modeling, and others. He currently works as a senior firmware engineer working on various projects for the Power Business Unit of ADI. He is currently working toward his master’s degree in electrical engineering at the University of the Philippines. He can be reached at marvinneil.cabuenas@analog.com.

(ID:50311312)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:fill(fff,0)/p7i.vogel.de/companies/69/30/693022b11e5db/logo.jpeg)

:quality(80)/p7i.vogel.de/wcms/e1/26/e126040bf1678b7f7f4cea8ef0ba062c/0123764690v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/02/d6/02d6c26b11d3584ad8061a3d6b6356b6/0123226106v2.jpeg)