PART 3: SEMICONDUCTOR MANUFACTURING Semiconductor circuit design: key chemical procedures

Related Vendors

Each semiconductor chip has a circuit design to operate and perform its designated function. These circuits are first designed, simulated, and tested on EDA (electronic design automation) tools. In fabrication facilities (fabs or foundries), circuits are often called patterns. The complex manufacturing processes enable the precise creation of detailed patterns on chips.

What after producing wafers?

The second article on the semiconductor manufacturing process explained the production of wafers in detail. The last step involved processing wafers to ensure their accurate shape for fabricating semiconductors. Post-manufacturing, wafers are sent for polishing and cleaning to ensure efficient microfabrication.

Wafer polishing

Wafers are polished to maintain the glass-like surface for microfabrication. Examples of adapted procedures include chemical polishing, mechanical polishing, chemical-mechanical planarization (CMP), and plasma polishing.

Wafer cleaning

After polishing wafers, cleaning is the next essential step to remove residual and unwanted particles. Ultrasound vibrations and plasma are two reliable cleaning procedures.

Semiconductor manufacturing processes

The chemical procedures in semiconductor microfabrication start from the deposition of thin films, tracing the circuit patterns, and removing unwanted layers from the wafer’s surface to the addition of metal layers. Fabs define thin film thickness to be less than 1 micrometer. The wafer surface over which thin film is deposited and chemical processes take place is called substrate. The section includes the process of deposition, oxidation, photolithography, etching, and metallization in detail.

Deposition

Deposition means “depositing”, “creating” or “tracing” thin layers of materials on the substrate at molecular levels. The layer can either be conductive, insulated, or protective. Each layer carries out different functions such as insulation, conductive pathways, protection, and many more.

The process is repeated on the substrate N times to get the desired thickness. Deposition can be carried out before or after the oxidation procedure, depending upon the nature of the layer. The last section “Metallization” discusses deposition techniques in the semiconductor manufacturing process.

Oxidation

A simple definition of oxidation is the addition of oxygen to a chemical process. In semiconductor manufacturing, an oxide layer creates a thin film that helps in microfabrication by providing insulation inside the chip.

- Gate formation: The dielectric property of the oxide layer (such as silicon dioxide) provides insulation for the gate terminal in MOSFET. The main function of the gate terminal is its insulation which allows a transistor to operate. Proper insulation enables channel creation for drain and source terminals.

- Inter-component insulation: ‘N’ components are connected inside the semiconductor chip. Closely spaced components can cause leakage current flow and short circuits, leading to the manufacturing of faulty chips. Insulation between components eliminates unwanted electrical connections and maintains the chip functionality.

- Passivation: Oxidation offers passivation- protection of semiconductor chips from corrosion and external environmental factors.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

The oxidation process grows thin films on the chip using thermal oxides, plasma-enhanced chemical vapor deposition (PECVD), electrochemical anodic oxidation, dielectrics (low K and high K), polycrystalline silicon, and metals like copper, aluminum, etc. The substrate is exposed to oxide at a temperature range from 700-1200 degrees Celsius and atmospheric pressure of 1 atm in a controlled environment.

In the semiconductor manufacturing industry, most fabs opt for the thermal oxidation process. Dry oxidation and wet oxidation are two thermal oxidation methods used in the industry to grow silicon dioxide for silicon-based wafers.

- Dry oxidation: The substrate is exposed to oxygen at higher temperatures in a controlled environment to grow a thick oxide film of higher breakdown voltage. Dry oxidation is followed twice in the sequence.

- Wet oxidation: Just as the name suggests, wet oxidation exposes the substrate to a mixture of oxygen and water vapor at slightly lower temperatures. The presence of H2O molecules grows oxide film at a higher rate.

Photolithography

A wafer is coated with a photosensitive material called a photoresist or resist. The wafer is brought into contact with a mask to transfer patterns on its surface. EDA tools are used to define circuit patterns for the mask.

Photolithography steps:

- Initially, the silicon-based wafer with an oxidized layer of silicon dioxide is sent for the photolithographic process.

- An adhesion layer is added to the surface.

- The substrate is coated with a light-sensitive material called a photoresist (positive or negative).

- Positive photoresist: For a positive photoresist, the exposed portion becomes more soluble, and the unexposed portion becomes insoluble in the developer’s solution. The masked area is removed in the lithographic process and the exact pattern remains.

- Negative photoresist: For a negative photoresist, the masked portion becomes more soluble, and the unmasked portion becomes relatively less soluble in the developer’s solution. The unmasked area is dissolved in the lithographic process and the opposite pattern persists.

- The wafer is rotated and pre-baked to remove the solvent.

- The wafer is sent in the optical lithography equipment.

- A UV light-generating source emits light onto the mask.

- The mask is a thin-flat glass, or quartz substrate with an IC circuit design pattern.

- Fabs implement the usage of yellow light as photoresist is insensitive to orange and red light wavelengths.

- The mask is bought either in direct contact or close proximity to the wafer.

- The equipment projects light onto the mask to transfer the geometry of the circuit patterns.

- The photoresist can block light through its opaque portion for tracing the pattern.

- The exposed/unexposed resist is dissolved in the developer solution which can be either acidic or basic in nature.

- The wafer is rinsed, dried, and post-baked for adhesion improvement.

- The photolithographic process is repeated step-by-step and layer-by-layer in the fab.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/65/5c/655c87f111972/202311-whitepaper-tektronix-coverbild.png)

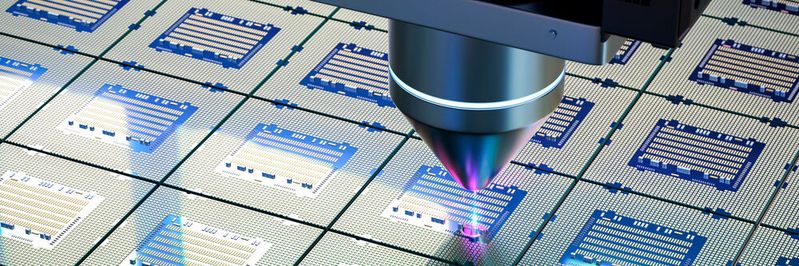

Etching

After photolithographic procedures, etching is the next step in microfabrication. The pattern transferred on the wafer’s surface contains unwanted portions and undesirable dust-like residues. The etching process, an acidic or basic process in nature, selectively removes the unwanted particles and layers for the circuit design pattern to remain on the wafer. In order to remove the unwanted material, the etching process can use chemical solutions or reactive gases, known as “etchant”.

The etching process is broadly classified into dry and wet chemical etching.

- Wet chemical etching: Wet etching removes unwanted layers from the substrate through the use of liquid chemical solutions.

- Dry etching: Dry etching techniques utilize plasma or gas with high-energy ions to chemically react and remove the unwanted layer from the substrate. An example of dry etching is plasma and reactive ion etching.

- Reactive ion etching: RIE uses chemically reactive gasses in the plasma state, the fourth state of matter, to eliminate undesirable materials from the substrate.

In simple words, etching is the selectively controlled process to remove unwanted particles from the substrate. Similar to photolithography, the etching process is repeated step-by-step and layer-by-layer in the semiconductor manufacturing process.

Metallization

The process of “metallization” is the addition of metal layers in the chip to allow current flow. A semiconductor chip becomes functional only when a path is created for the current to flow. In simple words, metallization connects various components, wires, and circuits together.

The metallization process can be implemented at multiple layers to create interconnects, ohmic contacts, and conductive pathways inside the chip. Some techniques used in fabs are physical vapor deposition (PVD), and chemical vapor deposition (CVD).

Metallization is an application of deposition in microfabrication to create electrical pathways. Two important metal layer deposition techniques are listed below. Industries use CVD extensively for metal thin film deposition.

- Physical vapor deposition (PVD): The physical vapor deposition technique involves “physically” depositing vapor molecules from the solid source material to the substrate. The solid source material is heated and vaporized before depositing it on the surface.

- Chemical vapor deposition (CVD): The chemical vapor deposition technique involves multiple gasses to react inside the chamber. The chemical reactions are triggered either by heat or plasma. The desired atoms and molecules, resultant chemicals, and byproducts of chemical reactions are deposited over the substrate.

"Semiconductor Manufacturing" article series

- Part 3: Semiconductor circuit design: key chemical procedures

(ID:49753697)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/b9/62b980cddf5d6/ceramtec.png)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:quality(80)/p7i.vogel.de/wcms/ef/f7/eff78f21c54995d45f8bfce6131c1b33/0125055923v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/09/6309df9835f3132935fb3e28945a8950/0128257234v6.jpeg)