BUSINESS OPERATIONS Resonac launches "JOINT3" Consortium to develop next-gen semiconductor packaging

Related Vendors

Resonac Corporation announced the establishment of "JOINT3," a co-creation evaluation framework formed by a consortium of Resonac and 26 other companies from various countries specializing in the semiconductor supply chain. The aim is to jointly develop materials, equipment, and design tools optimized for panel-level organic interposers—technology that utilizes organic materials to bridge different components on a circuit board—using a prototype production line for 515 x 510mm panel-level organic interposers.

Resonac will establish an "Advanced Panel Level Interposer Center (APLIC)" as the main hub for this initiative within its Shimodate Plant (Minami-yuki) in Yuki City, in Japan’s Ibaraki Prefecture. APLIC will house the prototype production line, which is scheduled to commence operations in 2026.

Here, the Consortium will accelerate development efforts by delivering verification results that closely mirror real-world structures.

In recent years, packaging for back-end processes has emerged as a key technology in the field of next-generation semiconductors. This includes 2.xD packages, whereby multiple semiconductor chips are arranged in parallel and connected via interposers, demand for which is expected to grow in line with the need for increased data communication capacity and speed. As semiconductor performance improves, interposers are becoming larger, and there is a shift from silicon interposers to organic interposers made from organic materials.

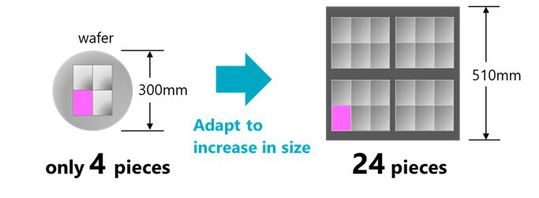

Conventional manufacturing methods involve cutting rectangular pieces from circular wafers. However, as interposers increase in size, the number of them that can be obtained from a single wafer decreases, posing a significant challenge. To address this issue, a manufacturing process that transitions from circular wafer shapes to square panel shapes is gaining attention, as it allows for an increased number of interposers to be produced from a given area of wafer.

As leader of the JOINT3 consortium, Resonac will propose R&D priorities, managing the operation of the prototype production line and driving the overall progress of the initiative. Through co-creation with participating companies, Resonac will also promote the development of materials optimized for panel-level organic interposers.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

Hidehito Takahashi, President and CEO of Resonac Holdings Corporation stated "JOINT3 brings together world-class companies from a variety of fields. Combining the complementary strengths and expertise of each company allows us to collectively address challenges in areas that were previously unreachable. This endeavor goes beyond mere technological development and will lead to solutions that address societal challenges. We are excited by the potential that this initiative offers."

Sumie Segawa, Vice President & General Manager, Division Officer, Corporate Innovation Division of Tokyo Electron Ltd., a participating company, commented, "Advanced packaging for AI semiconductors depends on miniaturization for high speed signaling and lower power, together with scaling for greater capacity. By combining JOINT3’s interposer technology with Japan’s superior materials and processing expertise, we will enable high quality, reliable manufacturing and jointly pursue further advances in AI semiconductors."

William F. Mackenzie, Group Managing Executive Officer, Ushio Inc., another participating company, remarked, " Advanced packaging is entering a new era, demanding innovation and collaboration across the ecosystem. As a core enabler, lithography is key to meeting these challenges. Through our Digital Lithography Technology and partnership in the JOINT3 consortium, Ushio is working with industry leaders to deliver the precision and performance the future demands."

Resonac will leverage the knowledge gained from the semiconductor packaging technology development consortia "JOINT" and "JOINT2," which transcend the boundaries of semiconductor equipment and materials manufacturers, as well as that sourced from "US-JOINT," which is being developed in Silicon Valley in the United States. By doing so, Resonac aim to contribute to technological innovation in next-generation semiconductor packaging.

| Name | JOINT3 (JOINT:Jisso Open Innovation Network of Tops) |

|---|---|

| Objectives | Accelerate the development of materials, equipment, and design tools optimized for panel-level organic interposers through co-creation with participating companies |

| Participating Companies (listed in alphabetical order) | 27 companies (as of September 3, 2025) Resonac Corporation, AGC Inc., Applied Materials, Inc., ASMPT Singapore Pte. Ltd., Brewer Science, Inc., Canon Inc., Comet Yxlon GmbH, EBARA Corporation, Furukawa Electric Co., Ltd., Hitachi High-Tech Corporation, JX Advanced Metals Corporation, Kao Corporation, Lam Research Salzburg GmbH, LINTEC Corporation, MEC COMPANY LTD., Mitutoyo Corporation, NAMICS Corporation, Nikko-Materials Co., Ltd., OKUNO CHEMICAL INDUSTRIES CO., LTD., Synopsys, Inc., Tokyo Electron Ltd., Tokyo Ohka Kogyo Co., Ltd., TOWA Corporation, ULVAC, Inc., Ushio Inc., ZUKEN Inc., 3M Company |

| Location | -Advanced Panel Level Interposer Center “APLIC” (Yuki City, Ibaraki Prefecture, Japan (within the Resonac Shimodate Plant) -Packaging Solution Center (Kawasaki City, Kanagawa Prefecture, Japan) |

| Activities | -Developing materials, equipment, and design tools for organic interposers using a panel-level (515 x 510 mm) prototype production line -Promoting development through co-creation by having material and equipment manufacturers produce common prototypes -Utilizing JOINT3 as a “training ground” for technology and equipment manufacturers to further enhance technologies related to panel-level organic interposers |

Get more information about the participating companies here.

(ID:50546285)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/b9/62b980cddf5d6/ceramtec.png)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:quality(80)/p7i.vogel.de/wcms/c0/3a/c03a16bc6a7a3446e3ec1eb0016d5aec/0124285381v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e2/d6/e2d6eadc2e131f89909e587e7ff0f0c5/0126751999v2.jpeg)