PART 1: FROM IDEA TO CONCEPT – GENERAL CONSIDERATIONS Introduction to Holistic 7D Power Module Design

Related Vendors

This article introduces a holistic 7D approach to power module design, integrating electrical, thermal, mechanical, and manufacturing aspects to achieve efficiency, reliability, and cost-effectiveness.

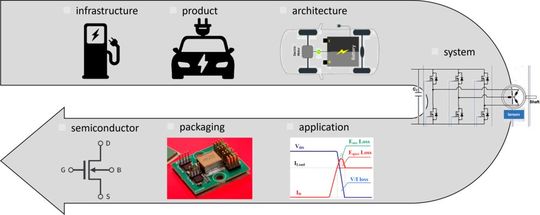

As power electronics continue to enable advances in electric vehicles, renewable energy systems, and industrial automation, the demand for highly efficient, compact, and reliable power modules (PMs) has never been greater. Positioned at the heart of every inverter in the power core, the PM defines both system-level performance and long-term reliability.

Traditionally, PM design is often reduced to three simplified steps: selecting the semiconductor, creating a layout, and manufacturing a plastic-cased power module. While this view may suffice for the basic development of power modules in certain conventional industrial applications, it overlooks the complex interplay of factors that ultimately determine the success of a design. This article aims to expand that perspective by presenting a broader vision of the power module architect’s role.

Conventional approaches, originating from wire-bonded plastic-cased power modules, treat electrical, thermal, and mechanical domains as separate design tracks, optimized in isolation. However, this fragmented methodology frequently introduces bottlenecks—excessive switching losses, limited thermal performance, or premature reliability failures—that constrain efficiency and shorten operating lifetime.

The high power density of modern power systems is mainly driven by two factors:

- 1. Optimized electromagnetic parasitics in the power and control loops, which reduce switching losses at higher switching speeds1). Novel packaging technologies offer additional design freedom and often outperform conventional solutions, but they require advanced EM design for the entire system rather than only for the power module.

- 2. Operation at higher junction temperatures (particularly in hard-switching applications) and/or the use of advanced cooling methods. Both aspects require a complex electro-thermo-mechanical design of the power module and its system integration.

A holistic, seven-dimensional design philosophy addresses these limitations by treating the power module as an integrated system, where (1) electrical, (2) thermal, (3) mechanical, (4) manufacturing, (5) quality assurance, (6) system integration, and (7) product qualification aspects are optimized in concert. This approach leverages advanced materials, innovative packaging concepts, and multiphysics simulation workflows to maximize power density without sacrificing manufacturability or reliability. By aligning performance targets with application-specific mission profiles, holistic design not only enhances efficiency but also ensures cost-effectiveness and robustness in mass production.

The first step in this process is a clear definition of the application environment. The system context—ranging from infrastructure constraints and maintenance cycles to regulatory norms and product lifecycle expectations—provides the boundary conditions for module architecture and costs. From this, concrete specification requirements can be derived (Fig. 1).

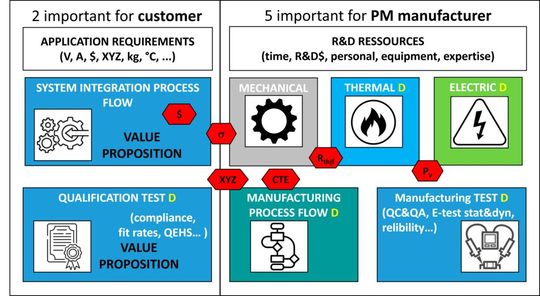

Most technical papers on power module design focus primarily on the aspects most relevant to manufacturers: electrical design, thermal design, mechanical design, and design for manufacturing. Quality control and testing are usually neglected at the concept stage of design. Nevertheless, the value proposition of the power module defines its success on the market. Therefore, the second step translates the specification requirements into a potential system integration process flow, compliance measures, and qualification criteria. These parameters define the PM’s value proposition and establish the initial constraints for semiconductor choice, mechanical interfaces, packaging technology, and thermal stack design under cost and timeline considerations.

In the third step, the first drafting cycle starts with balancing electrical, thermal, and mechanical aspects, taking into account manufacturability and quality control possibilities.

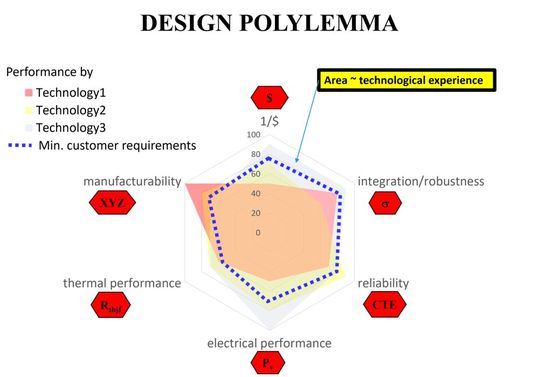

Solving the power module design polylemma, as shown in Fig. 3, requires identifying the optimum balance among six main parameters: electrical performance, thermal performance, reliability, integration and mechanical robustness, manufacturability, and cost.

The power module manufacturing technology (PCB embedding, transfer molding, …) itself is not the key to success. Solutions can usually be realized using several different technologies—or even a combination of them—while still meeting the original specification requirements.

Experience with a given technology increases the area of the polylemma hexagon, providing more design freedom and enabling improvements in performance, reliability, and value. Every manufacturing technology has its strengths and weaknesses. Design experience further enlarges the polylemma space, because it enables a smart combination of mature solutions with novel technologies, achieving a more reliable and cost-effective overall result than would be possible with a single manufacturing technology.

Such a multi-objective optimization leads to a Pareto frontier of potential conceptual solutions along with several other feasible alternatives. Depending on priorities, the best solution for a given application can be selected.

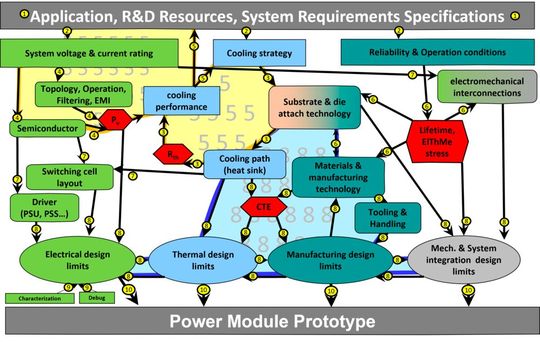

The next step is the translation of the chosen solution into a detailed design. This interdisciplinary challenge requires the use of multiple simulation tools and substantial process know-how. One possible algorithm to resolve these contradictions was presented in2). Each individual step can reach a high degree of automation.

Cooling performance, minimization of parasitic elements, selection of the thermal path approach, design for reliability, and manufacturability—as well as many other aspects—are addressed during this step.

The following parts of this article series will present application examples of the aspects discussed above for selected industrial and automotive use cases.

To be continued…

References

1) K. Klein, "Electromagnetic switching cell design for fast switching semiconductors," Dissertation, Technische Universität Berlin, 2023.

2) K. Klein, E. Hoene, and K. D. Lang, "Power module design for utilizing WBG switching performance," in *PCIM Europe 2019; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management*, May 2019.

(ID:50577909)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:quality(80)/thumbor.vogel.de/cDyBuURCAkYJma6g71KpNUUjv6E=/500x500/p7i.vogel.de/wcms/68/de/68dee728effd3/kirill-klein-bewerbungsfoto25.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/68/00/6800eb0040fb9/cobalt-vertical-aligned-bold.png)

:fill(fff,0)/p7i.vogel.de/companies/66/8b/668becd1c07eb/dowa-logo-word--1-.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/68/08/6808a2b3b6595/het-logo.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/af/9aafa5ad3d3d900a6e22adf6d06a9bf5/0126877798v2.jpeg)