THYRISTORS How to prevent Thyristor failure?

Related Vendors

Thyristors are known for their high-power handling capacity and latching-on property. However, they often fail during the turn-on and turn-off processes. If the dv/dt and di/dt are high enough, they are often the reason for failure. The article explains thyristor failure and potential solutions.

In electronics, dv/dt and dt/dt ratings are important factors for efficiency. These values represent variations in voltages and currents with time. Large variations in voltages and currents are not desirable in any electronics device— thyristors for that matter.

dv/dt: dv/dt is a derivative that depicts the rate of change of anode to cathode voltage with respect to time. If voltage changes too quickly, the value of dv/dt increases. On the other hand, if the voltage does not change quickly, the value of dv/dt is small. High dv/dt is an undesirable factor, hence dv/dt rating should be as low as possible. dv/dt rating is expressed in volts per microsecond.

di/dt: di/dt is the rate of change of anode to cathode current with respect to time. If the current changes rapidly, the value of di/dt increases. However, if the current remains stable and shows less variation, the value of di/dt decreases. High di/dt is an undesirable factor, hence di/dt rating should be as low as possible. di/dt rating is expressed in amperes per microsecond.

Thyristor Turn-off: dv/dt

When a thyristor is connected to an inductive load, such as a motor, current lags 90 degrees behind the voltage. When the voltage is abruptly cut, the current flowing through the thyristor drops below the holding current. The thyristor turns off. However, as the voltage leads, the voltage increases in the opposite polarity.

Due to the abrupt voltage cut-off and the leading voltage, the value of dv/dt is large. In simple words, there is a large voltage change in the circuit. As a result, large dv/dt can self-trigger the thyristor, leading to uncontrolled current flow. dv/dt is an inherent and undesirable characteristic of thyristor turn-off.

Thyristor Turn-on: di/dt

A high di/dt rating is more dangerous and undesirable than a high dv/dt rating. As described in our guide to thyristors, a thyristor does not turn on quickly. The minority carriers are injected into the junction J2 by a gate-triggering current pulse. Junction J2 undergoes avalanche breakdown. A rapid increase in initial current triggers the internal PNP and NPN transistors, forming a feedback loop that starts to conduct.

:quality(80)/p7i.vogel.de/wcms/af/07/af073e302fcca1153bcaca553175006c/0124143921v2.jpeg)

BASIC KNOWLEDGE

Thyristor: Definition, types, and more

The conductive region in a thyristor can sometimes fail to spread quickly throughout its area, starting from junction J2 and moving toward other junctions. The anode-to-cathode current rapidly changes. Some regions exhibit high current density, while others do not. These localized regions with high current density near the gate terminal are called hot spots.

A rapid change in current is responsible for the creation of hot spots. Hot spots experience thermal stress and localized heating. It increases the junction temperature. Thyristor can heat up beyond limits, leading to thermal runaway— permanent device damage. As a result, the di/dt rating should be as low as possible.

How to avoid thyristor failure and high dv/dt and di/dt?

dv/dt and di/dt are natural electrical responses in every circuit, including thyristors. If these ratings are high, thyristors become susceptible to electromagnetic interference and false triggering from internal junction capacitance. There are several ways to fight them and prevent component failure. This section describes some ways to fight large dv/dt and di/dt in thyristors.

Optical isolation

A transformer is connected between the gate current pulse generator and the gate terminal to avoid short circuit damage. The gate current pulse generator is the power element, whereas the gate terminal is a controlling entity. The gate driver is a bridge between power and logic elements.

Most thyristors require gate driver circuits to turn on and perform their basic operations. Gate driver circuits are responsible for turning and keeping them on. These circuits are often found on ready-to-use PCBs, specifically designed to achieve desired results and efficiency.

Thyristors use optical isolation between power and logic circuits. Optical isolation prevents false triggering, over-voltage, and damage. Generally, an optocoupler— an optoelectronic device consisting of an LED and a photodetector feeds the signal to the MOSFET driver stage in push-pull configuration.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

Sufficient triggering

To turn on a thyristor, the gate terminal should be triggered correctly. Else the thyristor may turn off quickly due to large di/dt. A current pulse with high peak current and duration must be applied to the gate terminal to turn on the thyristor at all operating temperatures.

A large gate current pulse for a longer duration enables quick thyristor turn-on. Once turned on, the triggering pulse should be kept low and constant till the thyristor settles in the latching operation and avoids early turn-off. Another way is to use a train of long pulses to ensure a proper thyristor turn-on process.

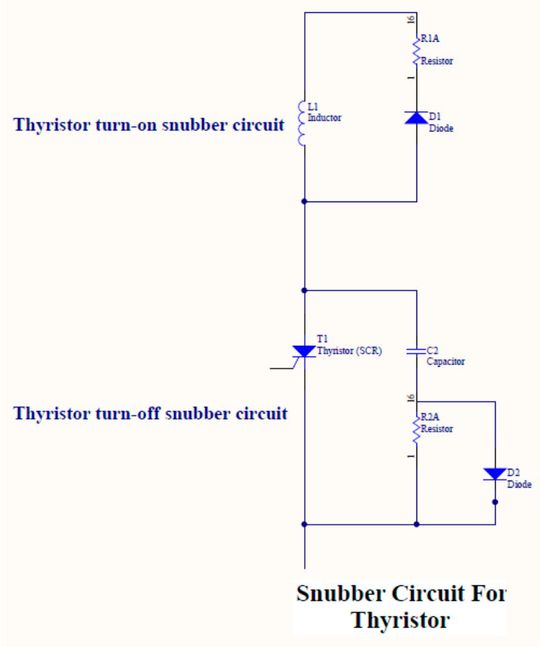

Thyristor snubber

Snubber circuits are high-energy absorbing circuits that provide an alternative path to unwanted voltage spikes and current surges. These circuits are not a part of device operation, but they are a part of protective gear.

Two separate circuits combine to form the thyristor snubber circuit. The inductor and capacitor are snubber elements that ensure low di/dt and dv/dt ratings. Auxiliary circuits consisting of diodes and resistors discharge these elements to avoid their involvement in normal thyristor operation.

Series inductor

The upper part of the circuit uses an inductor to eliminate large di/dt. The inductor L1 is connected in series with the thyristor T1 at the input. It is a type of stray inductance. During turn-on, the inductor L1 protects the thyristor T1 from a large di/dt. During the turn-off process, the resistor R1 and diode D1 discharge the inductor L1. In reverse blocking mode, the inductor L1 protects the thyristor T1 from large reverse currents.

RC snubber

The lower part of the circuit uses an RC snubber circuit to deal with dv/dt. The capacitor C2 is connected in parallel with the thyristor T1 in the lower part of the circuit. During turn-off, the capacitor C2 protects the thyristor T1 from a large dv/dt. It draws current to filter out high-frequency noise and snub voltage spikes. During the turn-on process, the resistor R2 and diode D2 discharge the capacitor C2.

Heat management

As thyristors are high-power devices dealing with voltage and currents in kilovolts and hundreds of amps, thermal management is crucial. Thyristors generate large amounts of heat in industrial and individual settings. Factories use large heat sinks, thermal pads, heat distribution mechanisms, and HVAC (Heating Ventilation Air Conditioning) to manage excessive heat.

References

- Mohan, N., Undeland, T. M., & Robbins, W. P. (n.d.). Power Electronics: Converters, Applications, and Design (2nd ed.). John Wiley & Sons, Inc.

- Rashid, M. H. (Ed.). (2001). Power Electronics Handbook. Academic Press.

PCIM Expo 2025: Become an exhibitor now

Let’s elevate your company’s global presence within the power electronics industry! Showcase your solutions, connect with the international community and shape the future at the PCIM Expo from 6 – 8 May 2025 in Nuremberg, Germany.

Learn more

(ID:50399801)

:quality(80)/p7i.vogel.de/wcms/a4/fd/a4fd7f7a395d6ecb4e79cfc558895b09/0129082772v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/62/a0/62a0a0de7d56a/aic-europe-logo.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/5f/71/5f71d5f92a5f6/2000px-rogers-corporation-logo-svg.png)

:quality(80)/p7i.vogel.de/wcms/af/07/af073e302fcca1153bcaca553175006c/0124143921v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3d/21/3d2163e1c620c06fa94740403dd297d1/0123860891v2.jpeg)