ENERGY STORAGE Could Potassium-Ion batteries power the next energy revolution?

Related Vendors

Potassium-ion batteries are emerging as a promising alternative to lithium-ion technology, offering comparable energy density, far greater material abundance, and lower costs, especially suited for large-scale renewable energy storage.

As the renewable energy transition accelerates, battery technology faces an inflection point. Lithium-ion batteries, the foundation of modern portable electronics, electric vehicles, and home storage systems, are running into hard limits. Lithium is scarce, its extraction is resource-intensive, and its price has surged as global demand increases.

To keep pace with the scale and sustainability demands of the future grid, researchers are looking beyond lithium. One of the most promising candidates is potassium-ion battery (KIB) technology, a technology that could combine the energy density of today’s lithium cells with far greater material abundance.

Professor Eunho Lim and colleagues at Dongguk University in South Korea have been mapping out this future. In a recent review published in Science and Technology of Advanced Materials, the team examined the electrochemistry, material design, and engineering strategies that could enable potassium-ion batteries to rival the performance of lithium-ion systems.

Why Potassium?

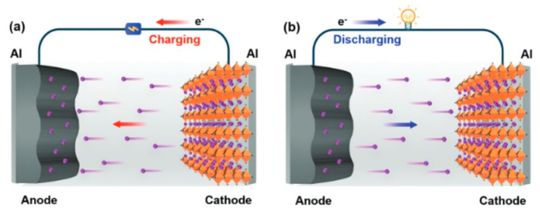

Potassium brings more than abundance to the table. Its redox potential of −2.93 V vs. the standard hydrogen electrode is close to lithium’s −3.04 V, which means it can achieve higher energy densities than sodium-ion batteries, the other leading lithium alternative. The chemistry offers a further manufacturing advantage: potassium does not react with aluminum in the typical voltage range of anodes. This eliminates the need for heavier, more expensive copper current collectors on the anode side, enabling lighter and more cost-effective cell designs.

However, potassium’s larger ionic radius compared to lithium presents a fundamental challenge. It affects how efficiently potassium ions can move into and out of anode materials during charging and discharging, and it influences the structural stability of those host materials over time. Addressing this requires rethinking electrode chemistry and architecture from the ground up.

Three Mechanisms for Storing Potassium

Inside the cell, the Dongguk University review identifies three main electrochemical mechanisms for potassium-ion storage: intercalation, alloying, and conversion reactions.

Intercalation is the most familiar to lithium-ion engineers, involving the insertion of potassium ions into the layered structure of the anode without breaking it apart. Graphite, the workhorse of lithium-ion batteries, can host potassium, but only with limited capacity and often with sluggish kinetics. This has led to the development of expanded graphite, heteroatom-doped carbon, and mesoporous carbon designs with wider interlayer spacing, improved conductivity, and optimized pore architectures. Nitrogen-doped carbon nanofibers, for example, have been shown to retain high capacity over thousands of rapid cycles, suggesting that with the right structural and chemical tuning, carbon can remain central to KIB anode design.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/61/09/6109228bdc722/kampagnenbild-webkon-pb-20210831.jpeg)

WEB CONFERENCE: THE FUTURE OF ENERGY

Renewable energies – chances & challenges for a clean future

Alloying takes a different approach, forming potassium-metal compounds with elements such as tin, antimony, or red phosphorus. These materials can store more potassium atoms per host atom, resulting in much higher theoretical capacities. The trade-off is severe volume expansion during the repeated alloying and de-alloying cycles. This mechanical stress can fracture the electrode, break electrical connections, and destabilize the solid electrolyte interphase (SEI). To counter these effects, researchers are embedding active alloy materials into conductive, elastic frameworks such as carbon scaffolds, MXene sheets, or metallic nanowire networks.

Conversion reactions involve a complete transformation of the anode material, such as metal oxides, sulfides, or nitrides, into metallic nanoparticles and potassium compounds. This mechanism offers some of the highest possible capacities but comes with large structural rearrangements, voltage hysteresis, and energy efficiency losses. To make conversion-type anodes viable, scientists are designing nanostructured composites that buffer volume changes and enhance conductivity, sometimes combining conversion with intercalation mechanisms to improve stability.

From Lab to Grid

While potassium-ion technology can leverage much of the existing lithium-ion production infrastructure, the chemistry demands new material engineering strategies. Potassium’s size can strain the host lattice, leading to particle fracture and unstable electrode–electrolyte interfaces. Matching the electrolyte composition to the electrode is critical for forming a robust SEI that is both ionically conductive and electronically insulating. Potassium salts such as KPF6 and KFSI, along with additives like fluoroethylene carbonate, are being optimized to improve Coulombic efficiency and suppress dendrite growth.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/62/0c/620cfcbf6f486/titelbild-webkon-pb-2022-03-15.jpeg)

WEB CONFERENCE: ENERGY STORAGE

Keys to the design and operation of battery storage systems

The first commercial opportunities for potassium-ion batteries are likely to be in stationary energy storage, where high capacity, low cost, and long cycle life are more important than extreme energy density. Grid-connected renewable storage, microgrids, and load-balancing applications could benefit from KIB systems designed for decades-long service with minimal maintenance.

Some laboratory anodes are already achieving thousands of stable cycles at high current densities, suggesting that the technology could meet the lifetime requirements for utility-scale deployments. As manufacturing processes mature and material costs remain low, potassium-ion cells could undercut lithium-ion pricing for large-format applications.

Lim’s team is now exploring advanced characterization techniques, such as in-situ transmission electron microscopy, to observe how potassium interacts with electrode materials in real time. These studies aim to guide the design of next-generation anodes that combine high capacity with mechanical resilience and chemical stability.

(ID:50524980)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/a0/62a0a0de7d56a/aic-europe-logo.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/66/8b/668becd1c07eb/dowa-logo-word--1-.jpeg)

:quality(80)/p7i.vogel.de/wcms/48/57/48571f6226e92e623dad2564ab397158/0123229696v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/58/7c58cec56e63a63af024e58dd8930e23/0126563932v2.jpeg)