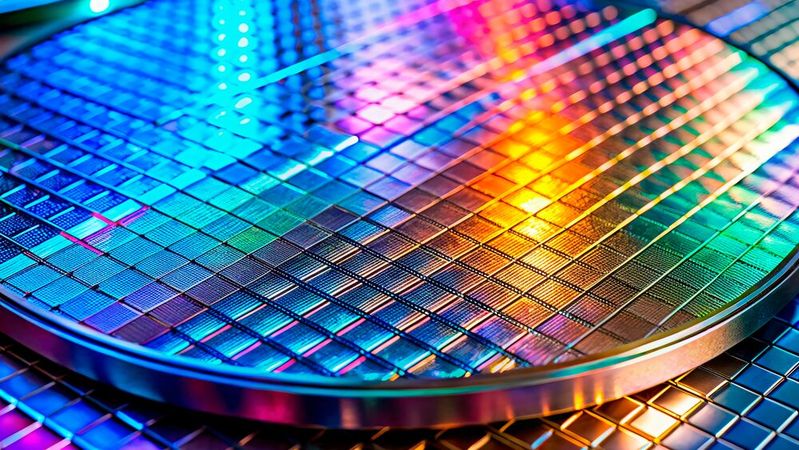

SIC MANUFACTORING Breakthrough in 300mm silicon carbide technology

Related Vendors

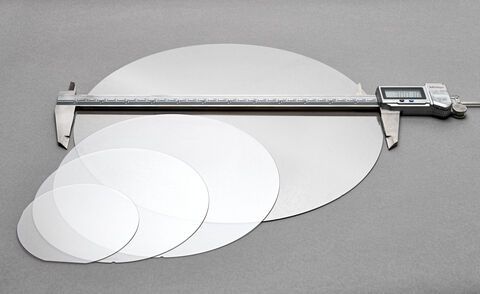

Wolfspeed, Inc. announced the successful production of a single-crystal 300mm (12-inch) silicon carbide wafer, describing it as an industry milestone. The company cited its silicon carbide IP portfolio of more than 2,300 issued and pending patents worldwide and said the development supports its path toward future volume commercialization of 300mm technology.

This technology advancement represents a major step forward for next-generation computing platforms, immersive AR/VR systems, and high-efficiency, advanced power devices. By expanding silicon carbide to 300mm, Wolfspeed is unlocking new performance thresholds and manufacturing scalability for some of the world’s most demanding semiconductor applications.

“Producing a 300mm single crystal silicon carbide wafer is a significant technology achievement and the result of years of focused innovation in crystal growth, boule and wafer processing,” said Wolfspeed Chief Technology Officer Elif Balkas. “It positions Wolfspeed to support the industry’s most transformative technologies, especially critical elements of the AI ecosystem, immersive augmented and virtual reality systems, and other advanced power device applications.”

Wolfspeed’s 300mm platform will unify high-volume silicon carbide manufacturing for power electronics with advanced capabilities in high-purity semi-insulating substrates used in optical and RF systems. This convergence will support a new class of wafer-scale integration across optical, photonic, thermal, and power domains.

:quality(80)/p7i.vogel.de/wcms/0c/5e/0c5e149a1c6928d929ac9070a63e989c/0126851656v2.jpeg)

SILICON CARBIDE

Wolfspeed debuts 200mm SiC materials for scalable manufacturing

Wolfspeed powered AI

As AI workloads push data centers to their power limits, the demand for improved power density, thermal performance, and energy efficiency will continue to accelerate. Wolfspeed’s 300mm silicon carbide technology will enable integration of high-voltage power delivery systems, advanced thermal solutions, and active interconnects at wafer scale, extending system performance beyond traditional transistor scaling.

AR/VR – Powering Optical and Thermal Integration

Next-generation AR/VR systems require compact, lightweight configurations that integrate high-brightness displays with expansive fields of view and effective thermal management. Silicon carbide’s unique material properties, including mechanical strength, thermal conductivity, and optical refractive control, make it ideal for multifunctional optical architectures.

Beyond AI infrastructure and AR/VR, transitioning silicon carbide to a 300mm platform represents a major step forward in scaling the production of advanced power devices. The larger wafer diameter enhances the ability to cost-effectively meet growing demand for applications including high-voltage grid transmission and next-generation industrial systems.

:quality(80):fill(efefef,0)/p7i.vogel.de/wcms/5f/fe/5ffedb2e0ffa6/listing.jpg)

Poshun Chiu, Principal Analyst, Compound Semiconductor, Yole Group said: “This 300 mm breakthrough is more than a technical milestone — it unlocks new opportunities for silicon carbide as a strategic material. It clearly demonstrates that silicon carbide is advancing to the next level of manufacturing maturity required for the coming decade of electrification, digitalization, and AI. It provides the market with a credible roadmap toward higher-volume production, improved economics and long-term supply assurance.”

(ID:50682038)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/78/107856328ef320cc081bf88e0baf95e8/0128685487v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/dc/5f/dc5f858b2eef27f3457df3e2e2d7024b/0128663152v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/62/b9/62b980cddf5d6/ceramtec.png)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/62/95/6295c25c8dc1a/schunk-sonosystems-300dpi.png)

:quality(80)/p7i.vogel.de/wcms/b0/11/b0111764a3aedddf61a60c50813acfd6/0127533227v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/21/de214c8f498277f6dc9fe036c41788be/0126176305v2.jpeg)