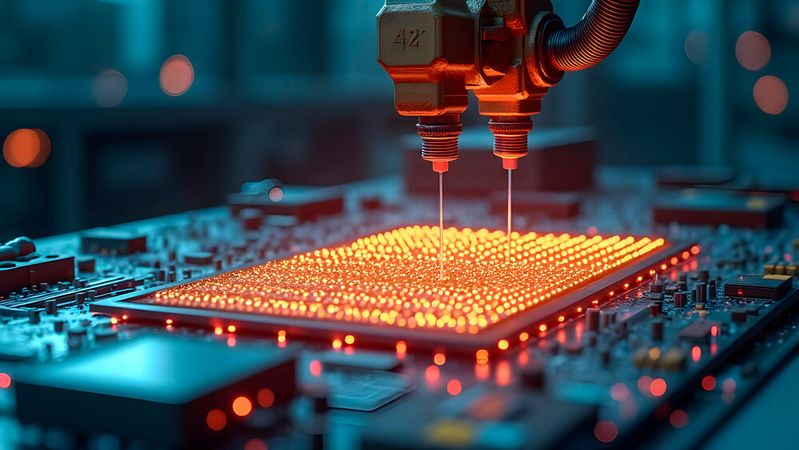

POWER SEMICONDUCTOR 200v bcd process targets next-generation automotive and data center power ics

Related Vendors

SK keyfoundry, an 8-inch pure-play foundry in Korea, announced that it has recently launched its fourth-generation 200V high-voltage 0.18-micron BCD (Bipolar-CMOS-DMOS) process and will begin full-scale product development with major domestic and global customers, targeting mass production within the year.

As vehicle electrification and the expansion of AI data centers continue to accelerate, market demand for high-voltage, high-efficiency power semiconductors is rapidly increasing. In particular, automotive electrical architectures are transitioning from 12V to 48V systems, while AI servers and data centers are raising operating voltages from 380V DC to as high as 800V DC to maximize power efficiency and density. Against this backdrop, the importance of process technologies capable of reliably withstanding high voltages above 100V while enabling efficient power control has never been greater.

The fourth-generation 200V high-voltage 0.18-micron BCD process newly introduced by SK keyfoundry features more than a 20% improvement in Rsp (specific on-resistance) and BVDSS (breakdown voltage), reflecting enhanced power efficiency and high-temperature robustness compared to the previous third-generation process. In addition, the process offers low on-resistance devices optimized for each operating voltage, minimizing chip area and power loss and thereby enhancing overall process competitiveness.

Notably, the process provides a Thick IMD option that enables the safe transmission of digital signals while blocking unwanted high voltage and noise between high-voltage, high-current PMIC devices utilizing BCD and HV MOSFET technologies. It also supports a wide range of embedded memory options, including SRAM, ROM, MTP, and OTP, as well as Hall sensors for precision motor control, further expanding design flexibility for high-voltage ICs.

:quality(80)/p7i.vogel.de/wcms/2c/ef/2cef65d84ca2bd65519e1831cbf9d458/0128092593v2.jpeg)

POWER MODULE

1200V SiC modules for E-mobility propulsion systems

SK keyfoundry's new process can be applied to the development of a broad range of products, including high-voltage power management and conversion ICs, motor drivers, LED drivers, and power supply gate drivers. Most importantly, it meets the stringent automotive reliability qualification standard, AEC-Q100 Grade 0, enabling immediate adoption in automotive electronic components that require high reliability even under extreme operating conditions.

"As AI servers and automotive electronic systems continue to require higher power, demand for BCD processes exceeding 100V is increasing rapidly," said Derek D. Lee, CEO of SK keyfoundry. "In particular, given the limited number of foundries capable of providing high-voltage BCD processes based on bulk silicon, the mass production of our 200V high-voltage 0.18-micron BCD process represents a meaningful milestone. We plan to continuously advance our process technologies in line with evolving customer requirements in the power semiconductor market."

(ID:50696553)

:quality(80)/p7i.vogel.de/wcms/bc/97/bc97cce107109a551f26fb8076ae1da8/0129190430v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/34/ab3461e7aabc1beab6f2598d09f1d9b4/0128949857v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/92/cd9200bfe196631a5fd7b5b85e25a5a6/0128944352v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/44/4d/444dda9649b5619c79d019c7dc1efcfc/0128974547v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/13/b313941dbf7adc57c6d144966106d82b/0129219607v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/56/a4/56a4d9b6ee131a7a00b8b89dabf108f9/0128979281v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/40/7d406bd959b3a9127c33a66157f9030a/0128339184v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/65/22/65223bc58811ced76adbfa7b5615d532/0129061536v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ea/20/ea20c0beb93f34ab43b28750644bbdca/0128983445v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/0a/b10a283cdf3e5f156781a7273c71a7e0/0129107484v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/23/ee/23ee4a97790d6009dbfd7d9577ffa723/0129220424v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/60/7e/607ec89d5d9b5/white-frame.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/dc/61dc0e8c2e420/dspace-logo-1000px-220107.png)

:fill(fff,0)/p7i.vogel.de/companies/68/c2/68c2b622b43e1/logo.jpeg)

:quality(80)/p7i.vogel.de/wcms/a5/d7/a5d71b175f1d77ef91789dacf49092de/0127601917v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/a0/7ba0a5453a2ba24e3edc852527ed7f27/0128662544v2.jpeg)