THERMAL MANAGEMENT 3D-printed heat sinks for chips and circuit boards in data centers

Sponsored by

3D-printed chip and board coolers open up considerable efficiency potential and save space and material. IQ-Evolution is now bringing the technology, which has already proven itself in automotive electronics, to the data center market.

According to the Borderstep Institute, data centers in Germany will consume almost 18 billion kWh in 2022 - and the trend is rising. Almost all of this electricity is converted into waste heat. It would therefore make sense to use data center waste heat. It is now also required by law in the Energy Efficiency Act (ENEfG).

Liquid cooling is necessary for computing power of 30 kW or more per rack, which is quite common in the AI environment. It delivers higher waste heat temperatures with more efficient heat dissipation, which simplifies the feeding of waste heat into secondary use circuits, such as district heating networks.

3D metall printing (LPBF)

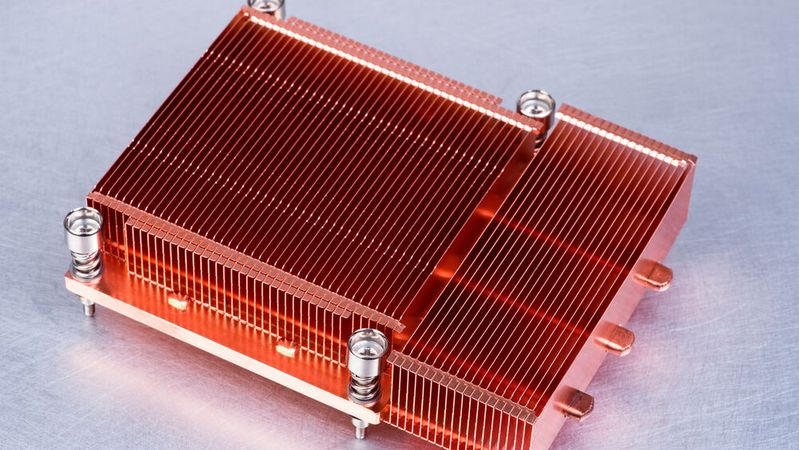

Recently direct chip cooling is used. Heat sinks are a key component of directly liquid-cooled chips and circuit boards. They are applied directly to the components to be cooled. A water/glycol mixture flows through them and transports the waste heat away.

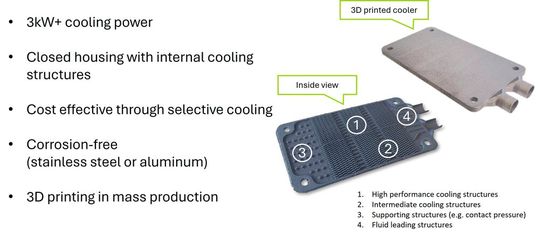

A relatively new production method for heat sinks that has been further developed and used by IQ Evolution is the 3D printing process Laser Power Bed Fusion (LPBF). The heat sinks produced in this way have already proven themselves in the automotive industry. The requirements for heat sinks are particularly high there.

LPBF produces burr-free and seamless heat sinks in any complex shape and from any material. During printing, powder is applied thinly and flatly to the work table and selectively laser-exposed. During exposure, the material melts and solidifies again in the desired shape. The work table then moves down 20 micrometers and the cycle is repeated.

For small formats, several heat sinks are produced in one print pass. In series production, several printing machines can be connected in parallel so that it can be scaled up quickly.

More efficiency, less space required

“We are convinced that our printed heat sinks and the associated properties can also bring significant benefits to data centers,” says Dr. Thomas Ebert, Managing Director of IQ Evolution. “That's why we are now also addressing the data center market.”

Because the heat sinks fit snugly against the chips, they transfer heat particularly effectively. The process also produces virtually no production waste. The thin wall thicknesses of sometimes only 150 micrometers also save material. Heat sinks can be designed to be more efficient at the hotspots of the structures to be cooled, such as the cores of multiprocessors, and more economical in other areas. The pressure resistance is still 60 bar.

The extremely flat shape and the lack of fans on the chip also save space in the rack. An example: The AMD Rizen Threadripper Pro gaming processor fits on just one height unit with a heatsink from IQ Evolution with greater cooling capacity - otherwise it takes up two. In terms of price, the heat sinks are comparable with other manufacturers despite their more complex shape and performance.

IQ Evolution is already negotiating with well-known integrators and OEM customers in the data center sector.

(ID:50233863)

:quality(80)/p7i.vogel.de/wcms/a4/fd/a4fd7f7a395d6ecb4e79cfc558895b09/0129082772v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/71/fd/71fdcc22d9a9bd2f42985f692c4aefa2/0128924236v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/54/94548eaecd020681e558d563bc48ba1d/0128926221v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/99/2999bb9af245dd31f4c837c1d9359046/0128923137v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/62/676279913d77e1db48eb5cbe9be4c767/0128937895v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/a2/0fa2b5bdc21e408fd73e637d226d5210/0128681532v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/6f/4f6faf0ca6f748a2967d6b5bba7c88e1/0128682406v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/52/ad52f7b5542eff15ba54ec354d31b50d/0128681536v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/1e/9c/1e9c45d6fcf2fb48dc47756e4cb20174/0128931043v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/42/8b4271e1bedea432ab03c83959e30431/0128818204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/5a/875a8fa395c1eec9677e075fae7f5e8e/0128793884v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/93/2f9364112e8c6ff38c26f9ba34d0f692/0128791306v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/d1/3cd1cacbceb792ba63727199c61ca434/0127801860v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/a0/5aa0436498af618297961fd54ab36cdf/0126290792v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/30/cb30ebdca7fcaea281749cb396654eb3/0124716339v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/b4/0bb4cdfa862043eac04c6a195e59b3e0/0124131782v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/68/c2/68c2b622b43e1/logo.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/af/9aafa5ad3d3d900a6e22adf6d06a9bf5/0126877798v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/25/a5/25a5f03b687b18a3dbff3e43b16c9075/0126765129v2.jpeg)